We take a look into the world of water injection, and why water/Meth kits can have benefits on your tuned car.

Adding water to a petrol-fueled engine may sound like a recipe for disaster, but it’s a practice that’s been going on for over 50 years. The principle behind it is to remove unwanted heat from the combustion process, and therefore aid engine cooling.

In a performance engine, a massive amount of heat is produced when the air/ fuel mixture combusts. The piston bears the brunt of this heat, and in many standard engines is kept cool by the introduction of the unburnt air/fuel mixture (which itself has a cooling effect) by conducting the heat through to the underside of the piston. This is constantly quenched by the engine oil (and is why some performance engines have piston-cooling oil jets), and also into the cylinder walls. These are kept cool by the coolant circulating around the engine.

But on turbocharged engines – and particularly on highly-tuned turbocharged engines – the heat produced at combustion is increased. To combat this, traditionally more fuel is added to keep everything cool. But adding excess fuel can also have detrimental effects.

As more and more fuel is added to prevent detonation and keep things cool, the speed at which the air/fuel mixture combusts will actually slow down. This causes a loss of power. Also, by adding extra fuel there is a possibility of experiencing bore-wash, where the additional unburnt fuel ‘washes’ away the oil from the cylinder walls. This can cause premature engine failure.

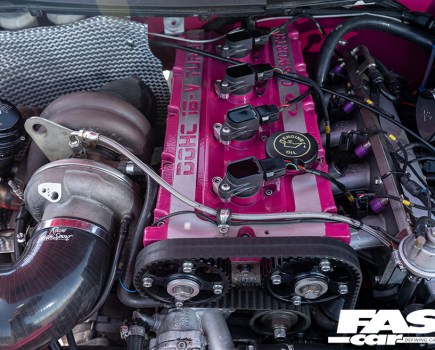

Devil’s Own kits, made in the USA, are popular on the drag racing scene.

Benefits of using water injection

This is where injecting small amounts of water can help. Usually, the water injected is mixed 50/50 with methanol. The water droplets provide the main cooling effect, while the combustible methanol effectively raises the engine’s resistance to detonation. The mixture should also include small traces of water-soluble oil, to prevent corrosion of the water injection and fuel systems.

The introduction of water injection can cool the air/fuel mixture quite significantly. The water is injected as a fine mist and the tiny droplets absorb some of the heat energy produced during combustion. This reduces the peak temperatures experienced, which in turn reduces the likelihood of pre-ignition/ detonation.

Another benefit of water injection is that more of the combustion energy is used to move the piston. As the water vaporizes, it turns into high-pressure steam. This then acts on the piston, potentially increasing power – albeit the effect is barely noticeable.

Using water/methanol injection means performance gains are easily obtainable. Reducing peak combustion temperatures and introducing methanol means higher compression ratios and/or higher boost pressures can be used without increasing the risk of detonation. Therefore, adding water to your engine is not as daft as it first sounds.

Stay safe when using Methanol

These injection systems are chemically compatible with a mixture of water and methanol. Most manufacturers of kits will strongly recommend this mix does not exceed a concentration of 50% methanol. Other than the obvious risks, this can also damage the systems flow sensors and often void the manufacturers’ warranty.

AEM warn Methanol is toxic and highly flammable. 100% Methanol ignites easily and burns with an almost undetectable flame. Methanol can be absorbed through the skin and even small amounts can cause blindness or even death.