Are you looking to upgrade your braking system for better performance? In this feature, we’ll dive deep into the debate of slotted vs drilled rotors and help you make an informed decision.

What are slotted and drilled rotors?

Before we start, let’s first examine what your stock brakes look like. In most cases, OEM brakes tend to use a smooth rotor with multiple cooling vanes in between two smooth surfaces. A set of plain rotors are the cheapest and easiest to manufacture, provides the most user-friendly pedal feel, and offers the lowest levels of noise and vibration. They are, as you’d expect, the perfect solution for a regular street car.

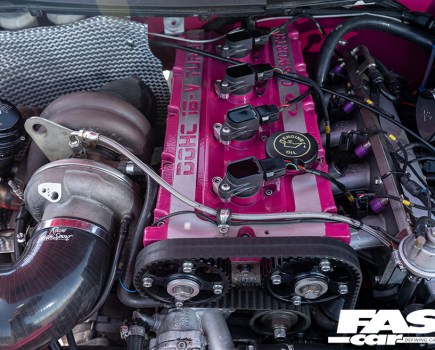

But we don’t drive regular street cars. We don’t mind sacrificing the odd squeak in return for improved hard braking. And the good news is, significant braking gains can be found by swapping to a performance brake rotor and suitable brake pads, without the expense and hassle of replacing the factory brake calipers. Upgrading your rotors and pads is no more difficult than regular replacement of stock parts!

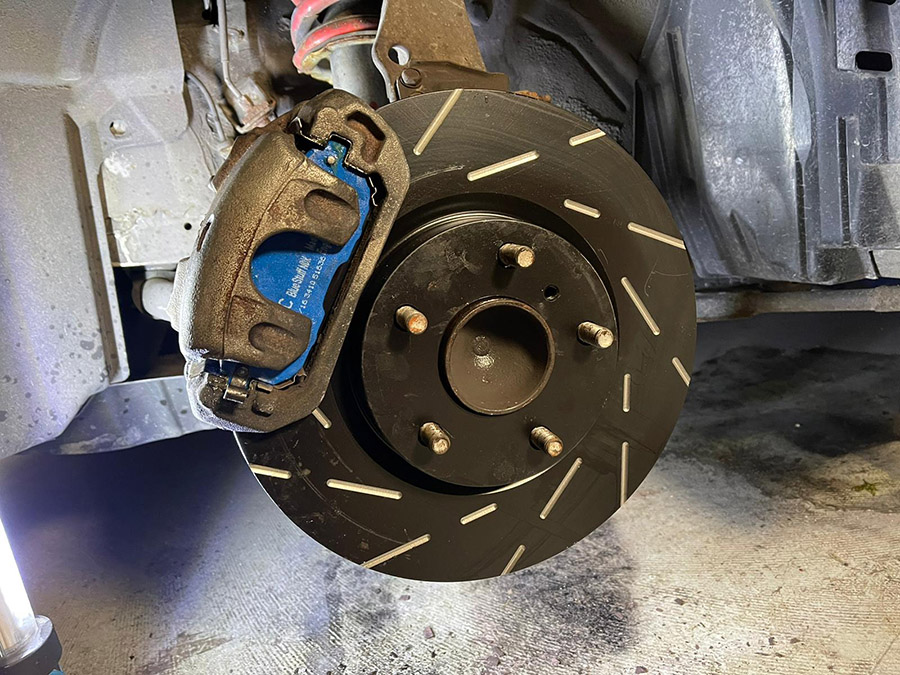

There are several options for upgrades, but the two main types of performance brake rotors available are slotted or drilled. Slotted rotors have grooves machined into the surface that dissipate heat and gases, while drilled rotors have holes that pass through the friction surface and into the cooling vanes in the middle of the rotor for the same purpose. Both improve braking performance and reduce brake fade. The choice between them depends on personal preference and your car’s specific needs and uses.

Understanding Slotted Rotors

Slotted rotors, designed with surface channels or slots, offer numerous benefits for braking performance. These slots promote consistent and reliable braking by allowing heat and gases to dissipate, thus preventing brake fade. Furthermore, slotted rotors excel in wet conditions due to their ability to remove water and debris from brake pads. It is crucial to note, however, that these rotors can produce noise and result in accelerated wear on brake pads due to increased friction. Despite these downsides, slotted rotors remain a popular choice for high-performance and race cars.

Understanding Drilled Rotors

Drilled discs (also called cross-drilled rotors), in contrast to slotted rotors, incorporate drill holes on the rotor surface. This design promotes heat dissipation and minimizes brake fade. By allowing better airflow, drilled rotors effectively cool down after intense braking, meaning the braking system is less likely to overheat and suffer brake fade. However, traditionally, drilled rotors have a higher likelihood of cracking when subjected to rigorous conditions. Therefore they tend to be preferred for street and road cars over race cars where extreme braking conditions occur.

Slotted Rotors: High Performance Braking for the Track

For track enthusiasts and performance-driven drivers, slotted rotors offer high-performance braking with precise control. These specialized rotors, featuring slots that aid in heat dissipation and debris clearance, are the ideal choice for drivers seeking ultimate braking performance on the track or during aggressive street driving.

With their superior responsiveness and improved brake feel, slotted rotors deliver enhanced stopping power and reliable performance. However, it’s important to consider the potential downsides, including increased noise and accelerated pad wear. By choosing slotted rotors, you’re opting for optimal braking power without compromising on control or performance.

What are the benefits of slotted rotors?

Slotted rotors offer numerous benefits for braking performance. These specialized rotors feature shallow channels or slots that enhance heat dissipation and combat brake fade. The sharp edges of these slots help provide better initial brake bite and improved stopping power, they also effectively remove water, dust, and debris from the braking surface and effectively clean the brake pad for optimal performance.

Slotted rotors are great in wet conditions too, by maintaining contact between brake pads and rotors. However, it is important to note that they may cause more noise and accelerated brake pad wear compared to other rotor types. When deciding between slotted and drilled rotors, carefully consider your vehicle’s specific braking needs.

What are the drawbacks of slotted rotors?

Slotted discs, despite their various advantages in terms of braking performance, are not without their downsides. One significant drawback is that the slots in the rotor can create stress points, which can lead to cracking or warping over time, compromising the overall effectiveness of the rotor.

Also, slotted rotors tend to be noisier than their drilled counterparts and may induce slight vibrations or pulsations during braking. These factors can have an impact on the overall driving experience and may not be suitable for everyone. When considering the use of slotted rotors, you need to consider any potential drawbacks carefully.

Drilled Rotors: Braking Upgrades for the Street

Drilled rotors provide notable braking upgrades for street use. These braking enhancements are achieved through improved heat dissipation and effective venting of gases and debris thanks to the holes on the disc surface. As a result, the risk of brake fade is reduced, and overall braking performance is improved. Furthermore, the extended lifespan of the brake pads can be attributed to better ventilation. But, drilled discs are not always the best aftermarket performance rotors for track use due to their susceptibility to cracking under extreme stress or heavy braking.

What are the advantages of drilled rotors for braking performance?

Drilled rotors provide numerous advantages for braking performance. With their cross-drilled holes, these rotors excel in dissipating heat efficiently, ensuring your brakes remain fade-free even during intense driving. The holes also prevent the buildup of gases and debris, maintaining a clean braking surface for optimal contact with the brake pad. This enhances overall braking performance, especially in wet conditions. Additionally, drilled rotors offer an attractive upgrade, adding a sporty and stylish element to your vehicle. So, when it comes to enhancing friction and ensuring smooth braking, drilled rotors are a better choice.

Are there any disadvantages to drilled rotors?

Drilled rotors, although visually appealing and offering better initial bite in wet conditions, come with significant downsides for braking performance. One major drawback revolves around the structural integrity of the rotor itself. The drilling process weakens the rotor by creating holes, increasing the likelihood of cracks or warping when subjected to heavy braking. Modern drilled discs use high quality materials (typically cast iron) and these ventilation holes can be cast in the rotor at production rather than drilled into the surface later, which minimises the likelihood of stress fractures forming at these points. However, whether drilled or cast-in, the holes can create an environment for water or debris accumulation, diminishing the braking effectiveness, particularly in unfavorable conditions.

So, which is better: slotted vs drilled rotors?

There’s no right or wrong answer. Both slotted and drilled rotors offer unique benefits and drawbacks for braking performance, and both are a huge step up from most stock braking systems. Slotted rotors are ideal for high-performance braking on the track, providing enhanced cooling and improved bite. On the other hand, drilled rotors are great for street driving, offering better heat dissipation and reduced brake fade. Ultimately, the type of disc you choose will depend on your specific driving needs and preferences. To learn more about choosing the right upgrades for your car, check out our other features and guides.