If you want to modify your car’s handling to the next level, upgrading your dampers is a necessity. Here’s everything you need to know about dampers.

Suspension tuning has always been seen as a bit of a black art. To improve handling, most will simply buy a car suspension kit, bolt it on, and have done. Those with a bit more pocket money will often opt for a set of coilovers, twiddle a few knobs, adjust the ride height, and think they then have the perfect handling motor.

But that’s not always true, is it? Some will find the setup too hard or too soft. They may also find that the car will handle better on some roads than on others.

Dampers are much, much, more involved than people think. There is an awful lot of brain power that goes into developing and producing one. That’s why we spoke to the experts to find out what goes into making the perfect suspension dampers.

What are dampers?

Before we start looking at the complex make-up of an uprated damper, first we need to understand exactly what one is and what it does. Often incorrectly called shock absorbers, the damper doesn’t actually absorb any of the shock from running over an uneven surface. That is the job of the springs. What the damper does is control the oscillation of that spring to give control over the ride quality. With dampers that are too soft for the desired use, the car will pitch and roll all over the place. This is because the damper won’t be able to react quickly enough to the oscillation in the spring. By the same token, a damper that is too hard will give a very bumpy and uncomfortable ride. The art of suspension tuning is getting this compromise just right.

What is the difference between monotube and twin-tube dampers?

There are two main types of damper design; twin-tube and monotube. As the names suggest, one design features two ‘tubes’ within the body of the damper. While the other uses the body itself to become the ‘tube’.

Twin-tube

These type of dampers have been around for a while and are what most standard production units are based upon. Inside the body are two tubes. A smaller, high-pressure capillary tube, and a precision-honed pressure tube.

The piston fits inside the larger of the two tubes (often referred to as the cylinder). It has precision-machined holes, which allow the oil within the damper to flow through it. When the damper compresses on the bump stroke, the piston is forced into the tube. The oil then flows through the holes in the piston (the shim stacks control the rate) and up the cylinder into the piston rod guide at the top of the unit.

The rod guide has a hole cross-drilled into it. This allows the oil to flow through it and into the capillary tube at higher pressure. The capillary tube then flows back down the length of the damper and into the damping control assembly at the bottom. When the pressure in the capillary tube exceeds the preload on the spring in the adjuster, the oil then bleeds off into the rest of the damper.

On the rebound stroke, as the piston is travelling back up the cylinder, the pressure above the piston forces oil through the capillary tube and into the adjuster screw. The movement of oil above and below the piston is known as the ‘high speed’. The movement of oil through the piston is known as the ‘low speed’.

Monotube dampers allow remote canister use.

Monotube

On a monotube damper the body itself becomes the tube. The piston is an exact fit for the inside diameter of the body. This allows the use of a larger piston than in a twin-tube damper. In turn, a larger piston offers more damping control because it displaces more oil. Also, a monotube damper is usually able to react quicker than a twin-tube damper.

The oil still flows through the piston in exactly the same way and is still controlled by the shim stacks used. The difference is in the adjustment. Instead of having the control valve at the bottom of the damper, the adjustment is made from the top. The piston rod is gun-drilled and has a shaft running through the center. Attached to the end of the shaft is either a needle valve. This alters the amount of oil allowed to pass through the center of the piston, or a spring that alters the amount of preload on the shims. Therefore, it controls the oil flow through the pistons.

Some high-performance monotube dampers have remote reservoirs. They work in the same way as single-bodied dampers. However, rather than all the oil being stored in the one body, there is, as the name suggests, a remote canister. This has several advantages over a single-bodied damper. One of which is the ability to carry more oil. This helps with cooling and degrading issues, especially on endurance race cars.

But the main advantage over a single-bodied unit is that a remote canister allows adjustment of both the high and low speed settings on the rebound stroke.

On twin-adjuster dampers, bump and rebound are adjustable independently

Damper adjustments

The art behind a good damper is in the way it is built. You cannot expect to fit a damper designed for another application and simply adjust it to suit yours. It will never work how you want it to.

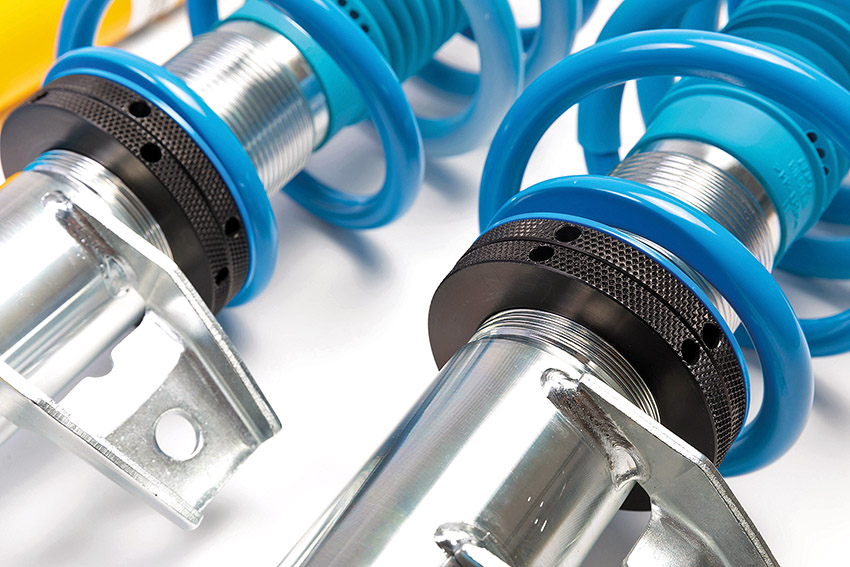

Having said that, most performance dampers have an element of adjustment built into them. This can vary from simple ride-height adjustment on coilover-type dampers to four-way adjustment of high and low speed settings on both bump and rebound of the damper.

Ride-height adjustment is fairly self-explanatory. The spring platform is adjustable up and down the length of the body by a simple thread, thus altering the ride-height of the car.

Twin-tube dampers often adjust bump and rebound through the same adjuster

Single adjuster

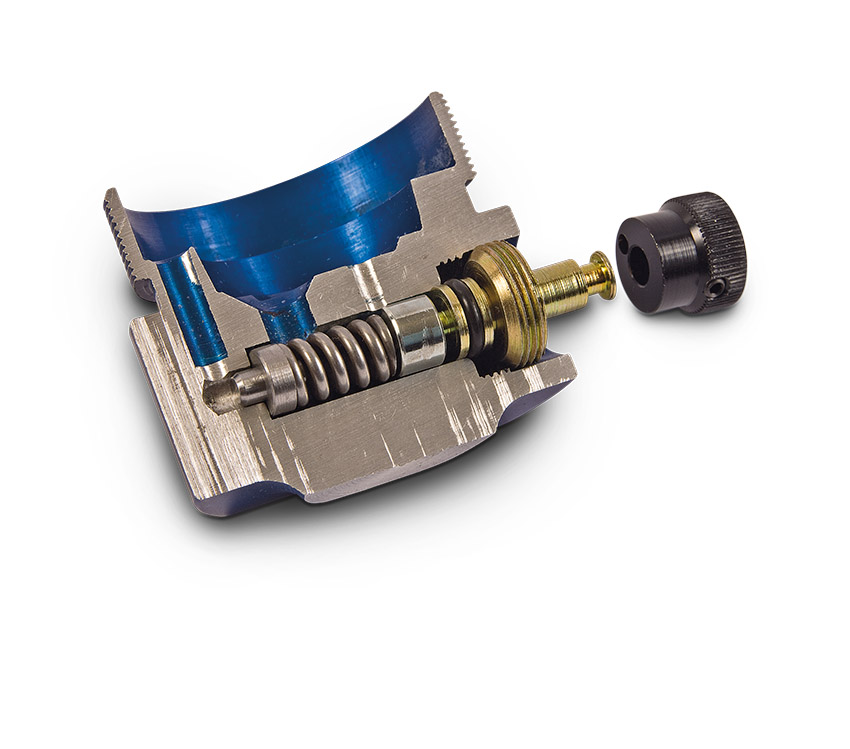

When you start looking at the bump and rebound adjustment, things start to get a bit more complicated. On a twin-tube damper, the most common adjustment is for both the bump and rebound on one adjuster at the bottom of the damper body. This works in a similar way to a bleed valve. When the piston moves either up or down within the cylinder, the rate at which the oil can flow through the piston determines how stiff it is.

The rate at which the oil flows through the piston depends on the shim stacks or valves used. But, if you also allow some of the oil to bypass the piston altogether by going through a bleed valve instead, you can alter the stiffness of the damper.

This type of adjuster sits in a damping control assembly at the bottom of the damper. It comprises a blanking plug, a spring, and an adjuster screw. The screw allows more (or less) preload to be put on the spring. When the oil in the capillary tube reaches a pressure that exceeds this amount, the blanking plug is forced back. The oil from the capillary tube is then allowed to bleed through, therefore giving control as to how stiff the damper is.

Ride height is adjusted by raising or lowering the threaded spring platforms

Twin adjuster

For separate bump and rebound control on a twin-tube damper, the bump is controlled in a similar way with an adjuster screw at the bottom of the damper. But, the rebound is adjusted from the top of the damper. The piston rod will have a shaft running through the center with either a needle valve or a spring and a plate at the end of it. The needle valve setup will allow more, or less, oil to flow through the center of the piston. Therefore, avoiding the shim stacks and giving a softer setting. The spring and plate type setup will allow more or less preload to be put on the shim stacks themselves. Therefore, altering the rate at which the oil can pass through the piston.

On a monotube damper, the bump and rebound can both be controlled by a single adjuster. Or, they can be controlled independently in a similar way to that used in a twin-tube damper.

Rebound control

Monotube dampers with a remote reservoir adds more control, this time adjusting both the high- and low-speed settings on the bump or compression stroke. The rebound settings are adjusted in the same way as normal. However, the bump is controlled by a needle valve for the low-speed and a spring for the-high speed. When the damper is on the compression stroke, the oil is forced into the remote canister through either the needle valve or the spring valve. Which route it takes depends on the speed at which the oil needs to flow.

For example, going round a bend the car will pitch and roll, and the movement of oil will be relatively slow and progressive. In this situation, the oil will be able to flow through the low-speed needle valve.

Now imagine the car runs over a kerb. The compression of the damper will be very fast and aggressive. The oil will need to move into the canister very quickly. As the oil won’t be able to flow through the needle valve quickly enough, the pressure will build up and open the spring on the high-speed adjuster, and therefore take this route.

The pinnacle of adjustable dampers are four-way units. These have independent adjustment for both the low- and high-speed settings on the bump control, and low- and high-speed settings on the rebound control. These are very expensive units, though, and are not common in race cars, let alone road and track cars.

Shim stacks control the oil flow and therefore damper stiffness

What are shim stacks on dampers?

Within a damper there is a cylinder. Within that cylinder there is a piston. The cylinder is filled with oil and the piston has holes that allow the oil to pass through. The rate at which this happens determines the damping force.

It is not just a case of changing the size of the holes in the piston, though. To fine-tune the way oil can pass through the piston, shims are used to partially block the holes in the piston.

These shims are thin pieces of sprung steel of varying thickness and diameter. When the oil passes through the piston, it will bend the shims to pass through more quickly. The amount the shims can bend depends on the thickness, diameter and number of shims used. Obviously, a thinner, larger diameter shim will bend more easily, and at less pressure, than a thicker, smaller diameter shim.

The shims are used on both sides of the piston. Shims on the top side of the piston control the oil flow when the piston is being forced into the cylinder. In other words, the bump settings. Contrastingly, the shims on the underside of the piston control the oil flow when the piston is moving back up the cylinder. In other words, the rebound.

Shim stacks can be tuned specifically for individual applications

Spacer Shims

The shims are held in place by a spacer shim, then a plate of the same diameter as the piston, and then finally a securing nut. The thickness and diameter of the spacer shim also influences how much oil can pass through the piston. This is because it restricts the amount of movement of the blanking shims. If you have a spacer shim with a thickness of 1mm, for example, the blanking shims can flex 1mm to allow more oil through. If you have a spacer plate of only 0.5mm thick, obviously the blanking shims can only flex 0.5mm to increase oil flow.

It is also possible to shim stack progressively by initially fitting a thin shim the same size diameter as the piston, then fitting slightly thicker, smaller-diameter shims on top of that. This will allow oil to quickly pass through the first shim. However, it will become progressively more difficult for the oil to pass through. Therefore, progressively increasing the damping force. This can be applied to either side of the piston, so can be used to control both bump and rebound.

Gas is used to take up the oil displaced by the piston rod on full compression

Gas-filled dampers

When you hear the term ‘gas-filled’ dampers it doesn’t mean they are filled with gas instead of oil. It means they are charged with both gas and oil. A purely gas-filled damper would be no good at all. Gas is compressible and would offer the car no damping force whatsoever.

It is because gas is compressible, though, that it is used. Without gas, the damper cannot be completely filled with oil and there has to be an air gap. This is to allow space for the oil that piston rod displaces as it moves in and out of the damper. Without the air gap, the damper would simply hydraulically lock.

But the gap itself can cause cavitation and aeration of the oil, reducing the performance of the damper. The use of gas eliminates this problem. This is because it can compress enough to compensate for the volume of oil the piston rod displaces, and allows the unit to be completely filled with oil to avoid cavitation problems.

Therefore, the amount of gas used in a damper needs only to be equal to the amount of oil the piston rod displaces.

In twin-tube dampers, a gas bag or close-cell matting is used

Gas bag or gas-filled dampers?

On a twin-tube damper, a gas bag is inserted into the body of damper, around the outside of the two tubes. When the piston rod is forced into the cylinder, the oil it displaces causes the air bag to compress.

Rather than using air bags, many manufacturers now use an oil-resistant close-cell matting. It works in exactly the same way as an air bag. It’s compressed by the oil displaced by the piston rod. It, too, only needs to compress enough to equal the amount of oil displaced by the piston rod.

On a monotube damper, the bottom of the unit is charged with gas. The gas and oil sections are separated by a floating piston. There is a circlip on the inside of the damper that stops the floating piston from rising all the way up the damper, and the gas is kept underneath this piston. When the oil is displaced by the piston rod entering the damper, the oil forces the floating piston to compress the gas trapped beneath it. Like the gas bag and the close-cell matting, the amount of gas only needs to be equal to the amount of oil that the piston rod displaces.

Active dampers allow the car’s ECU to alter the damper settings while driving

What are active dampers?

Many modern performance cars now have active damping control systems. These types of system can be known by many different fancy-sounding acronyms, but all are very similar in the way they work, and all have the same goal: to remove some of the compromise between the level of ride comfort on offer and the performance potential when used in anger.

How active dampers work

The way active damping works is very complex in practice, requiring various sensors mounted all over the car and a very clever ECU to interpret these inputs and make sense of everything. But in theory the idea is quite simple when you break it down. Going back to looking at how a monotube damper works, we still have the shim stack controlling the oil flow through the piston, and we still have a gun-drilled hole through the center of the piston rod.

But rather than having a manual adjuster controlling the oil flowing through the center of the piston rod (the knob on top of the damper body), this is controlled by electronic valves. This means the amount of oil flowing through the piston rod and therefore bypassing the shim stack can be directly controlled by the damping ECU.

And this is what allows us to have various suspension modes on modern cars. For example, a ‘comfort’ or ‘normal’ mode might see this valve wide open, meaning less oil needs to travel through the shim stacks, giving a softer setting, whereas a ‘sport’ mode might see the valve half-open, meaning only some of the oil can bypass the shim stack, resulting in a slighter firmer setting, while a ‘track’ mode might see this valve fully closed, meaning all the oil needs to flow through the shim stack, giving the firmest setting possible.

Fast response time

It’s not quite as clear-cut as that, though; these valves are continuously being adjusted at fraction-of-a-second intervals, and the modes are more of a base setting for how the ECU tells the dampers to respond. For example, the active damping system can respond so quickly it can detect when you stand on the brake pedal and firm up the front dampers to reduce the car’s tendency to dip its nose under heavy braking.

The same is true when you’re cornering and accelerating, resulting in a suspension system that is always at the optimum setting for the conditions.

MagneRide-type dampers

Some active dampers can also alter the settings by changing the physical properties of the oil used. These are known as magnetorheoligical dampers. They use special oils containing metallic particles, along with electromagnets to affect the oil’s viscosity. When current to the electromagnet is increased the oil behaves like a thicker fluid, therefore making the whole damper feel stiffer and firmer. When the current is dropped, the oil is free to move around more easily and behaves like a thinner fluid, softening the damper effects.

Active damping systems like these are very good for those of us who benefit from the compromise between comfort and performance, so are ideal for fast-road cars, but seldom seen on out-and-out motorsport machines.

Guide from Fast Ford magazine.