Wet sump vs dry sump: which is best? Well, let’s take a look at the oiling system options for your engine, and help you decide what you need.

Lubricating oil is the most vital fluid for any internal combustion engine, even more so than the fuel itself. An engine dry of oil could easily destroy itself simply being span by the starter motor, long before it even mattered if there was fuel in the tank. For this reason, oil starvation needs to be avoided at all costs, and achieving that should be high on your list of priorities when tuning an engine.

Sumps are the pan area at the bottom of the engine that the lubricating oil returns to after being forced around the engine via the oil pump(s), and there’s two main designs in existence: wet sump, and dry sump. While they both serve the same basic purpose as a part of the engine’s lubrication system, their design, and especially the overall system design, varies wildly between the two. This feature will explain it all, showing you both how these systems work and what would be the most suitable setup for your own car.

What is a wet sump?

A wet sump is the traditional oil system design for the vast majority of production cars, and is named as such due to the sump section of the engine, i.e. the part that bolts to the bottom of your engine block is also used as the engine’s oil reservoir. This in turn doesn’t mean the sump section of a dry sump setup is literally dry, but it certainly isn’t a deep sump holding massive amounts of oil like a wet sump setup does.

On an automotive wet sump the oil is sucked up and pumped around the engine under pressure by a single internal oil pump and then returns to the sump via gravity. On small engines like lawnmowers there’s often no pump as such, and instead a paddle wheel in the sump literally throws the oil around the inside of the engine, but for automotive applications that isn’t used.

Wet sump advantages

While not the ultimate oiling system, wet sump setups are by far the most common oil system design for automotive use for many reasons. Simplicity, low price, ease of service and repair, compact dimensions, and reliability are all traits that mean wet sumps are the go-to setup for the vast majority of production cars and trucks.

Wet sump disadvantages

Wet sumps are far from perfect, especially for very high performance use, and this is where dry sumps normally are used. Firstly, wet sumps are relatively tall, many inches taller than dry sumps, which means an engine’s overall height is greater. That can cause fitment issues as well as raising the cars center of gravity, which is detrimental to handling.

The main disadvantage however is the potential for the G-forces of hard cornering, acceleration, and braking, to make the oil slosh to one side, away from the oil pump pickup. In turn, that would starve the engine of oil and potentially destroy it in a very short period of time.

Sump and pickup design can certainly help that issue though, especially if the sump has any internal oil control devices like baffles and trap doors. In fact, many hugely fast race and rally cars still use a wet sump with no issue at all, but it’s not the ideal solution and these issues need to be a consideration on any high performance vehicle.

What is a dry sump?

First up, a dry sump is not dry! It’s not a literal bathtub of oil like a wet sump, but it is still constantly covered in oil, albeit a small amount in comparison.

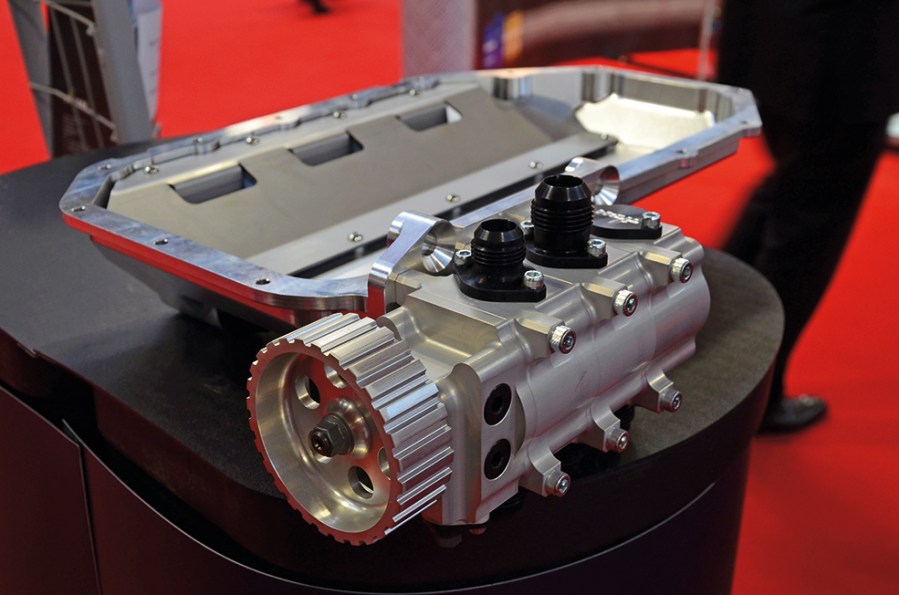

Dry sump systems have a very shallow sump that is simply used for the oil to travel back to after being pumped around the engine, and it is instantly sucked out by an external oil pump or indeed multiple pumps, often called stages, of the dry sump system. Those are ran from a toothed belt system from the engine’s crankshaft.

As a very basic explanation of the system, you have the sump, which an externally mounted scavenge pump system sucks the oil from and pumps it to a remotely mounted oil tank. Then, a pressure pump setup takes the oil from the tank and feeds it back to the engine’s lubrication points.

The reality of dry sump systems is that they are far more complex than that, with multiple pump stages, most commonly multiple scavenge pumps, mounted on a common crankshaft along with the pressure stage pump. This allows for an efficient yet compact design. The setup options don’t end there either, with various oil cooling, vacuum, and anti-aeration options fitted throughout the system.

Dry sump advantages

The main advantage of a dry sump system is the zero chance of oil starvation unless a component fails, which is the main disadvantage of a wet sump system where it’s always a potential issue no matter how good the system is. It doesn’t end there though, as the shallow sump allows for you to mount the engine much lower, aiding center of gravity. What’s more, you can mount the external oil tank anywhere in the car, so they are often mounted in the rear of front engine cars to help with weight distribution.

A dry sump system also allows the fine tuning of oil and crankcase pressures that is very hard on a traditional wet sump system. This includes allowing the crankcase to run under vacuum, which can be very beneficial to engine performance. Controlling oil temperatures is also far easier with a dry sump and external oil tank too, and perhaps most importantly, it massively helps reduce aeration of the oil. One thing most people don’t realize is wet sump setups naturally create very aerated oil with high rpm, causing oil to look like a frothy milkshake as it’s more air bubbles than lubricating oil. As you can imagine, that’s far from healthy for your engines bearings!

Finally, as dry sump pumps are external and modular, you can add additional pump stages depending on requirements, not to mention they can be easily serviced and repaired. As a result, dry sump oil systems can be custom specified to the needs of you and your engine in great detail.

Dry sump disadvantages

The main reason dry sumps are uncommon on production vehicles is the simple fact they are complex, and if tampered with by someone without a true understanding of them, could quickly lead to a badly damaged engine. While wet sumps are fairly fool proof, dry sumps are a high-end design that, while great, have a far greater potential for user error.

Even basic jobs like oil changes are far more complex with a dry sump system, and it goes without saying that the masses of external oil lines and other components make things far more involved than any wet sump design.

With the complexity and sophistication of dry sump systems also comes cost. There is no two ways about it, dry sump systems cost a lot of money, especially if converting a wet sump system to an aftermarket dry sump setup, putting them out of the price range of the average user.

Last, but certainly no means least, is that they require more maintenance and care purely as they are external. Wet sump systems literally have the engine and sump protecting all components from the elements and foreign object damage, but dry sumps have an external drive belt and pulleys that if damaged would instantly cause engine failure, not to mention relatively fragile pumps, lines, and tanks. So, care must be made to protect them, and they certainly aren’t fit-and-forget like the wet sump systems most of us are used to.