We take a closer look at one of the key areas of any internal combustion engine. Here’s our comprehensive fuel system guide.

The basics of a fuel system are simple enough to understand. However, when it comes to upgrading that fuel system (something you’ll need to do when tuning your engine), things can start to get surprisingly complex.

Various fuel delivery systems are available, but the type we’re interested in for this feature is the most common system; electronic fuel injection. The principle is very simple. The tank stores fuel, the pump takes fuel from the tank to supply the engine, and the injectors feed your engine with the required amount of fuel at the right time.

There are more components and certainly a lot more variables that you need to consider. Let’s take a closer look and find out the truth about fuel injection systems.

Fuel tank/cell

Everybody knows what a fuel tank is for, but on many highly-tuned cars people replace the standard tank with a performance fuel cell. These cells are stronger and less likely to leak in the event of a crash or roll over. They can be almost any size you require, and often baffled, negating the need for a separate swirl pot.

Fuel pump

The fuel pump’s job is to pump fuel from the tank (or swirl pot) to the injectors. Modern fuel pumps are electric, although older cars and some race cars use mechanical pumps. Some Sierra RS500 Cosworth race cars used a backup mechanical fuel pump driven off the cams.

Most modern fuel injection pumps can cope with the flow requirements of moderate power increases. However, upgrading the pump manages the fuel demands of highly-tuned engines.

A powerful single pump is preferred to twin-pump setups these days

Upgraded pumps come in a huge variety of shapes and sizes, some of which are capable of flowing over 1000bhp-worth of fuel.

But don’t think bigger is always better, it’s not. You can have a fuel pump that flows too much for your engine’s requirements. While an oversized fuel pump won’t over-fuel the engine itself (the fuel pressure regulator prevents this from happening), it will mean fuel pumped around the system happens too often. This can result in a loss of performance and increased risk of detonation due to the fuel being heated up.

Specific fuel coolers are available to cure this but are seldom seen outside endurance racers. It’s better to get the correct sized pump in the first place.

Fuel Filter

As you’d expect, a fuel filter removes foreign objects that may block the injectors or cause damage to the engine. Most standard filters can usually cope with the power increases we see. Tip, remember to change it frequently. It’s a filter, so by its very nature it will become blocked over time. If unchanged, it could potentially cause a lean-running engine. Larger ‘race’ items are available for big-power engines and those running more exotic fuels but aren’t really needed for fast road cars.

Fuel feed and return lines

The fuel feed line connects the main fuel pump to the fuel rail. It’s usually made of metal or reinforced rubber hose. It’s important that any hose is capable of handling high-pressure fuel. A normal rubber hose will degrade and can even burst under the pressure. For big power, larger diameter fuel lines often needed. However, surprisingly, a chunk of power can be achieved with seemingly small-diameter fuel lines.

A return line allows the excess fuel that the regulator bleeds off to return to the fuel tank (or swirl pot). The fuel here isn’t under any pressure, so you must make sure the return line is of a suitable size. If it cannot flow enough, it will become a restriction and cause increased fuel pressure.

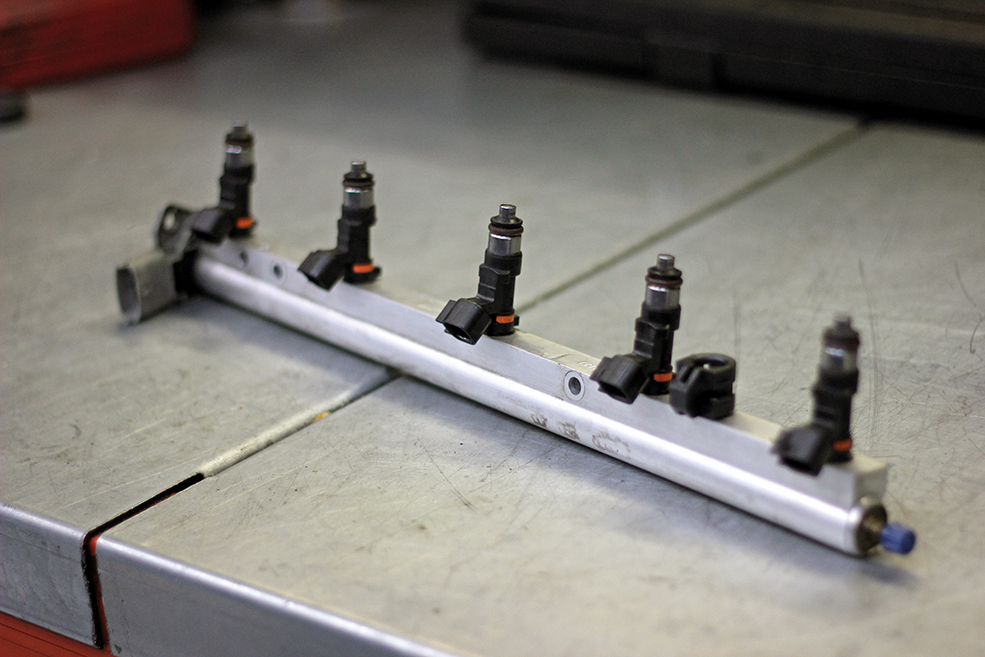

The fuel rail holds the injectors

Fuel Rail

The fuel rail is where the injectors mount. In essence, it’s simply a solid metal bar with the fuel coming in one end and going out of the other, with outlets for the injectors along the way. The pressure regulator mounts on the fuel rail too. Performance fuel rails generally feature a larger bore size and a higher flow rate. On some applications, they even have inlets at both ends and a central outlet. This provides a more consistent fuel flow under extreme use.

Fuel system guide – Injectors

Fuel injectors are small electronic solenoids controlled by the car’s ECU. They open at precise moments, and for exact amounts of time. This means they can supply the correct amount of finely atomized fuel to the engine. There are countless injector options available. As a result, finding the right parts for your engine’s requirements isn’t too hard.

Most factory-fit injectors have room for mild power increases. However, for big power hikes, larger injectors are a must. Larger injectors can deliver more fuel but can be harder to control at low pulse widths. This is especially true with less sophisticated ECUs, making for less refinement at low rpm. As a result, getting the right injector can be somewhat of a balancing act.

Fuel pressure regulator

The pressure regulator usually sits on the outlet side of the fuel rail and maintains a set pressure at the fuel rail by allowing excess fuel pressure to ‘bleed off’ into a return line back to the tank. Regulators are generally simple spring-loaded valves that open at a particular point (typically 3.5-bar).

All aftermarket regulators are fully adjustable. This enables fine-tuning of the static fuel pressure at the fuel rail. Many regulators also reference boost/vacuum from the engine (usually via a small pipe from the inlet manifold). They automatically adjust the fuel pressure to increase or decrease in parallel with the manifold pressure.

Modern ECUs allow for much better control of larger capacity injectors

What is a swirl pot? Fuel system guide

On highly-modified cars, fuel swirl pots often installed between the fuel tank and the main fuel pump feeds the engine. A swirl pot is a small-capacity, tall and baffled tank, usually around two liters in capacity. It’s used to prevent fuel surge when cornering, accelerating or braking hard. It makes sure there’s a constant supply of fuel to the main pump. Swirl pots are generally fed from the fuel tank by a low-pressure secondary pump or ‘lift pump’, as well as from the excess fuel returned via the fuel pressure regulator.

Single or twin pump?

It’s not uncommon to add a second fuel pump to keep up with the required flow of big-power engines. However, this creates a potential risk that you should be aware of. If one fuel pump fails, the single remaining pump will not be able to supply the required amount of fuel, so the pressure will drop, the car will run lean, and the engine will fail. A large, single fuel pump would be a safer option because if the pump fails the engine will just stall. Oddly, this is a situation where you’re better off with the car just stopping completely, rather than driving around with a lean-running engine that will be causing extensive (and expensive) damage. With new fuel pumps and good wiring, you’re unlikely to have a problem, but this is certainly a factor worth considering.

Extra injectors can be mounted side-by-side…

Two injectors per cylinder? Fuel system guide

You have probably noticed that some cars run two, and in rare cases, three, injectors per cylinder. There are two main versions of this: side-by-side injectors like on Escort WRC cars, and stand-off injectors like the Sierra RS500.

There are three main reasons for having multiple injectors per cylinder: older engine management systems can struggle to control large injectors accurately; massive fuel flow requirements are beyond the capabilities of a single injector; and the fact that secondary injectors placed further away from the inlet port will lower inlet temps – potentially increasing performance and reducing the risk of detonation.

The danger of running multiple injectors is the same as using multiple fuel pumps – single injector failure. If an injector fails, that cylinder will run lean and is likely to suffer expensive damage. Again, this risk is minimal with new components and well-built electrics, but the risk is still there.

In-tank or inline fuel pump

We’re sure you might have guessed, but an in-tank pump is submerged in the fuel tank, and an inline fuel pump is placed within the fuel feed line shortly after the fuel tank outlet. Most newer cars have in-tank pumps, and while these are effective, cars with uprated in-tank pumps tend to be more susceptible to fuel surge when cornering hard than inline pumps. To solve this problem, it’s usually wise to also install a fuel swirl pot feeding an external, inline pump. A fuel cell with inbuilt baffles to prevent fuel surge should help prevent the surge problem, but on standard fuel tanks at least, the baffles fitted may simply not be enough for hard track use.

Fuel system guide – Injector cleaning

Restoring injectors through cleaning can be a vital part of the tuning process, especially if using old or second-hand components. Fuel is rarely perfectly clean, hence the need for a fuel filter, but even they aren’t totally fool proof. Because of this, the injector will slowly start to clog and lose performance. Unless the problem is severe you may not immediately notice it, and if you buy a set of used injectors you may not realize one is blocked until it’s too late and you’re staring at a melted piston. Injector cleaning and flow testing is vital to make sure your engine is safe and running at its peak performance.

Injectors are cleaned in an ultrasonic bath and are tested and, if needed, adjusted on specialist flow testers, usually made by injection specialist ASNU.

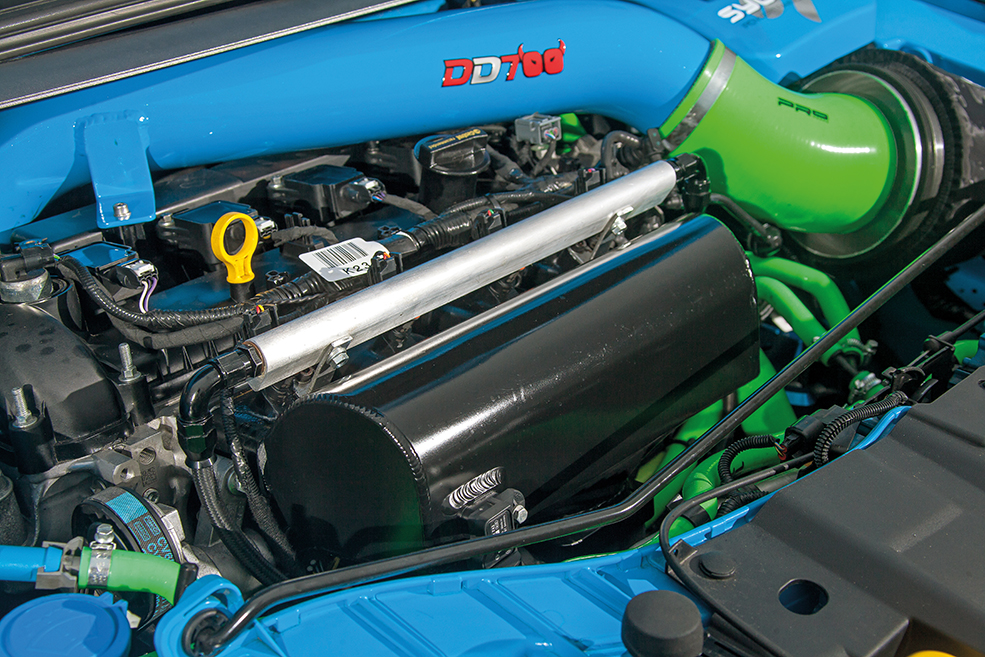

High-performance high-pressure fuel pump upgrades are the key to DI tuning

Direct injection

The latest generation of Fords, most notably the EcoBoost engines, utilize direct fuel injection (DI). The basic concept is the same as normal electronic fuel injection, but the fuel is injected directly into the combustion chambers at very high pressure rather than into an inlet manifold, and then being allowed to enter the combustion chamber via the inlet valve.

This is a more efficient way of injecting fuel and means there’s more potential for higher compression ratios and higher boost pressures on standard pump fuel… Plus overall improved drivability, better fuel economy and reduced exhaust emissions.

The standard direct injection components do have their limits, though, just as the traditional port-injection systems. On EcoBoost engines, for example, a high-pressure fuel pump is mounted on the engine and is driven from a cam lobe. The pressures are much higher than traditional port injection (up to 200-bar fuel rail pressure), but that doesn’t mean the OE parts can flow enough fuel to support all of our goals.

On big-power engines, a high-performance high-pressure fuel pump from the likes of Xtreme-DI is required – sometimes the pump alone is enough to supply the increased fuel delivery required, but for highly tuned engines the pump will need to be matched with high-flow injectors too. These components don’t come cheap; a high-pressure pump and set of 2000cc injectors for the 2.3 EcoBoost costs over $3000.

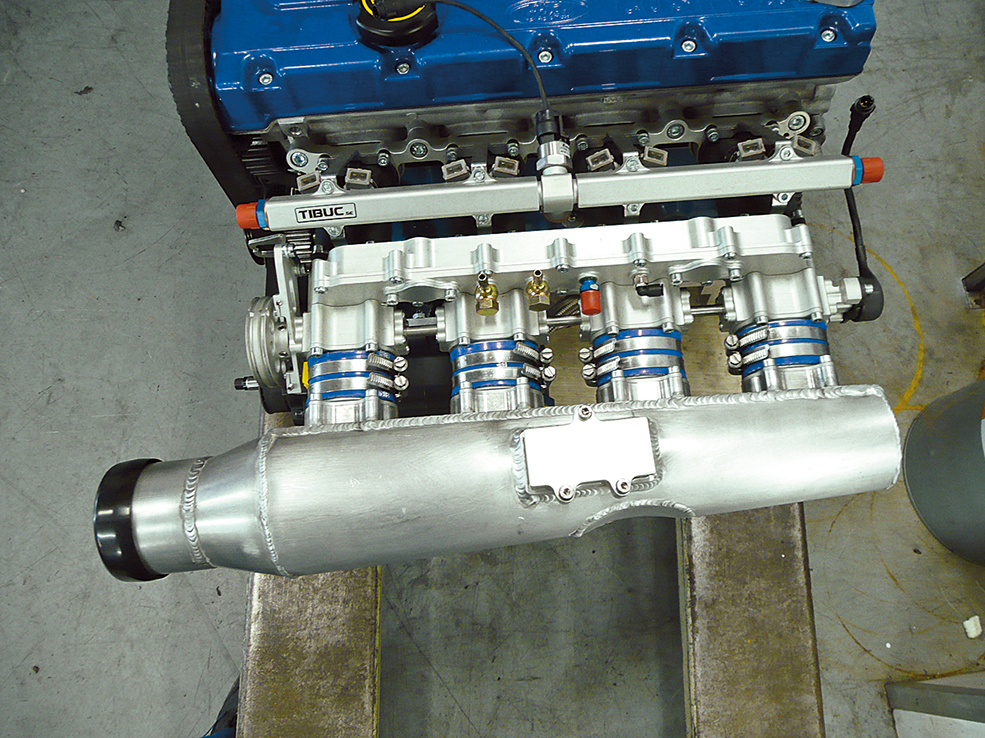

Fuel system guide – Port and Direct Injection

Before high-performance high-pressure DI pumps were readily available, tuners used to supplement the DI injectors with another set of traditional port-injectors. In effect, this is like having two fuel systems running simultaneously; one direct-injection, and one port-injection. It adds to the cost and complexity. However, it is a great way of supplying the extra fuel needed if no aftermarket upgrades exist. Modern high-performance upgrades offer a neater installation, but the option of adding another bank of traditional injectors (usually in the inlet manifold) is always a handy alternative.

Adding a port injection system means you can retain the OEM DI components, but still deliver the extra fuel when it’s needed