One of the least understood but important upgrades on any highly tuned car is to the chassis itself, and we give you the low down.

What are chassis upgrades?

It’s not the most common term you’ll hear in the tuning world as the chassis is the car’s load bearing framework. It’s effectively the car’s skeleton, so modifications involving it are generally very in-depth to say the least. Despite this, you won’t find any serious track or race car without at least one of these modifications, and some with almost all of these, so read on and see how car chassis upgrades can transform its performance.

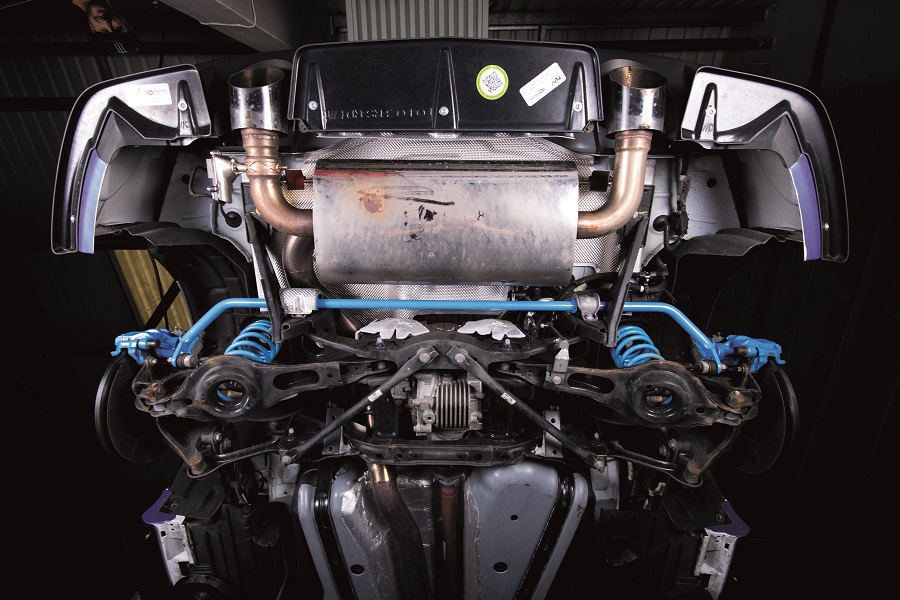

Chassis bracing

By far the most commonplace and accessible chassis upgrades is bracing. While some cars have much stiffer chassis than others, almost all production cars can benefit from increased chassis stiffening, especially when you have track use in mind. The most effective form of chassis bracing are ones that keep the suspension mounting positions from flexing, which are mostly in the form of front and rear strut braces. These tend to be cheap and very easy to fit, and can be very effective upgrade. Beyond this, what chassis bracing upgrades exist depend on the car itself. However, the most common types of chassis bracing exist under the floor, to stiffen the chassis rails, braces that stiffen the area from the windscreen to the front suspension and rear sub frame/axle braces.

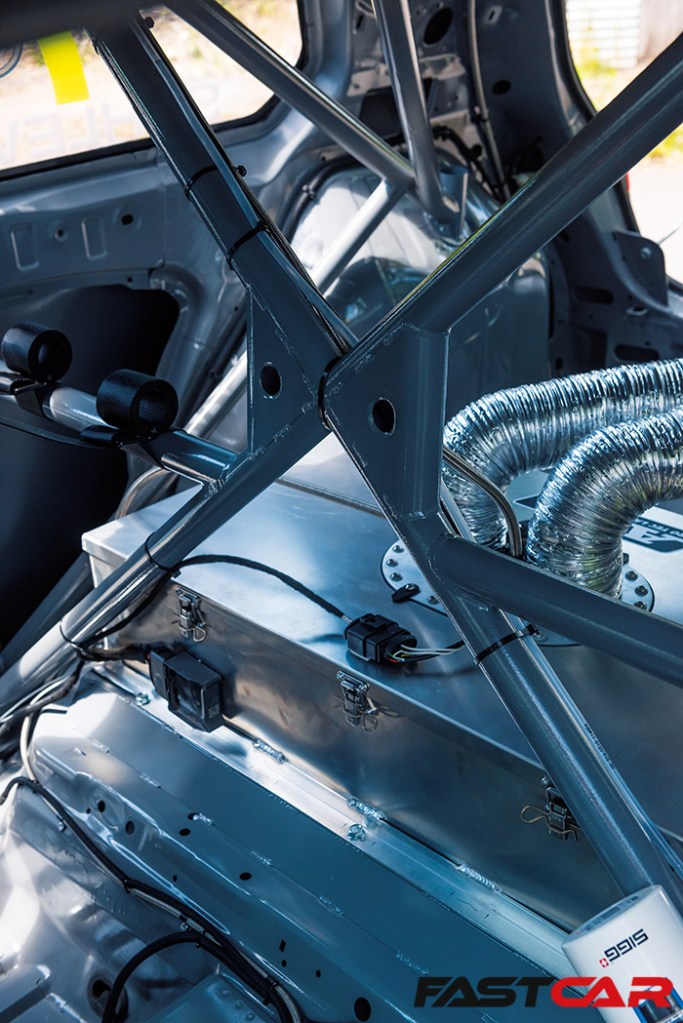

Roll cage

The next step up from simple bolt-on chassis bracing, a roll-cage has a dual role, both to increase driver safety in the event of a crash, and to massively improve chassis stiffness. Roll cage design has a huge effect on how much stiffer it will make a chassis, as while all will stiffen the main chassis area, more comprehensive cages tie in to both front and rear suspension mounting areas and even brace along floorpans, making for a hugely stiff chassis.

Be sure to visit our guide to roll cages for more info.

Seam welding

From the factory, almost all vehicles are spot welded together to create a stiffness the manufacturer considers acceptable from a performance point of view, while also taking in to account cost and safety aspects like crumple zones. Because of this, they are rarely as stiff as they could be, and that’s where things like seam welding comes in. This is taking the factory spot welds up a notch, with rather than one small weld every inch or so, welded seams are added, usually an inch or two long, then a small gap, then another.

Exactly where and how much this is done on the chassis depends on the application, and is very labor intensive as the car needs to be stripped to a bare shell with all seam sealer removed, but is commonplace on almost all race cars due to the positive stiffening effect it has. It’s one of all time greats when it comes to chassis upgrades.

Weight reduction

While blindly cutting metal out of structural areas of a cars chassis is a terrible mistake that can literally wreck a vehicle, weight can be removed without compromise if done correctly. The most obvious example is once the chassis has been significantly stiffened with a roll cage or similar, as then there is likely parts of the chassis that no longer serve a significant purpose from a stiffness point of view; though you’ll need an expert’s opinion on this before cutting!

Other parts of the chassis may simply be there for reasons that are not vital from a pure performance point of view, such as the chassis rails either end of the car beyond the suspension mounting points, spare wheel wells, and so on, which can safely be removed or replaced with lighter components.

Our guide to car weight reduction is packed full of tips and tricks for making your car lighter.

Spaceframe

This takes the roll cage and weight reduction aspects and combines them to create something far better than both; albeit in exchange for an incredible amount of time, money, and talent.

A space frame chassis is basically a full custom tube frame car skeleton, with little to no extra metal welded to it. Exterior panels that create the car’s look, including floor and roof, are simply attached afterwards with no structural function at all.

Doing this creates an incredibly stiff and lightweight structure, especially as the exterior panels can then be made of very thin materials as they are now purely cosmetic, so much so that many spaceframe chassis race cars can have a multitude of different bodies placed over the space frame, making them look like very different cars, despite being identical underneath.

As you can imagine, this is a massive and expensive job, as little to none of the original vehicle is left after this, but for the ultimate race car, a space frame chassis is the way to go.

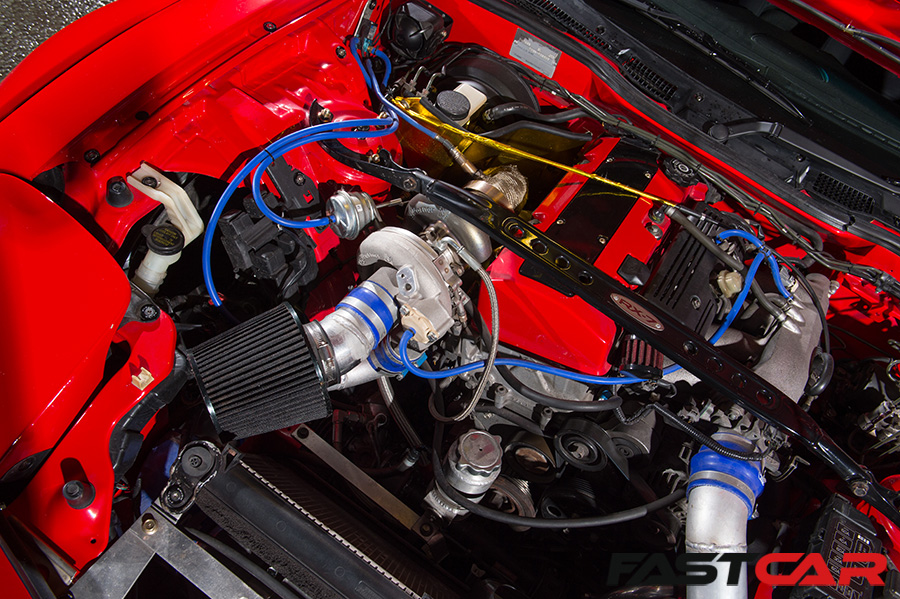

Engine/Drivetrain changes

Another reason chassis upgrades are done is to allow major engine or drivetrain changes, such as a much bigger engine, moving the engine to a non-standard position, or converting the chassis to allow different wheels to be driven than it was originally designed to, such as a front wheel drive to rear wheel drive conversion.

The work involved here can range from relatively minor changes to things like the firewall or transmission tunnel to mount the new engine and gearbox, right up to extensive chassis modifications that can sometimes go as far as a complete floorpan swap, to convert a car from, for example, transversely mounted front wheel drive, to longitudinally mounted all-wheel drive.

Suspension design

If you want to drastically alter the suspension design on a car, for example changing to a double wishbone design on a track car, or converting the rear end on a car from or to a solid rear axle, chassis upgrades will be needed. While of course the main component changes are suspension related, to mount these parts the chassis will require significant upgrades, both in mounting points and in many cases a complete re-design of chassis rails and more. This is a job for a chassis expert, but many companies, especially drag and circuit race car builders, specialize in this exact job.

For regular suspension upgrades, be sure to check our guide on the best car suspension brands in 2023.