Discover how to identify a slipping clutch or a noisy release bearing with our guide to car clutch problems. These are the most common car clutch problems and warning signs to be aware of.

Understanding the warning signs that your clutch might be on the way out should form part of your overall car maintenance. But, high revs and not being able to select a gear aren’t the only symptoms you should be wary of. In this guide we’ll take a look at what a clutch is and each of the issues it may develop, as well as how to identify them.

What is a car clutch?

A clutch in a car relates to the components that help to transfer the power from the engine to the gearbox and, in turn, to the road wheels to move them. These components include a friction plate, which enables the rotation of the engine’s flywheel to be transferred to the gearbox. There’s also a clutch cover which helps to guide that friction plate. A release bearing helps the connection to the gearbox. And in some cases, a hydraulic slave cylinder to help with operating the clutch pedal.

All of the components can have their issues, which results in a range of common car clutch problems. Read on to discover the best ways to fix them.

Be sure to check out our guide to clutches to find out when and why you would upgrade them when tuning.

I can’t get my car in gear

If after pressing the clutch pedal down, you can’t select a gear, there may be a problem with the clutch cable or the clutch fluid.

If you can’t select first gear, for instance, try pumping the clutch pedal a few times, then try again. And if this is more successful, check whether your car has a hydraulic clutch. If it does, check the fluid level for the clutch. There may be a separate reservoir inside the engine bay, or it may share the fluid with the brake reservoir. In most cases, top up with DOT 4, but check your workshop manual.

If pumping the clutch helped, but the fluid level is okay, there may be a problem with the clutch slave cylinder. The seals inside it can fail or air can get trapped in the system. Bleeding the clutch fluid may help. And overhauling or replacing the slave cylinder can also fix this problem.

Problems with the gear change cables or rods can cause issues with gear selection, sometimes fixed by fitting new ones or replacing any bushes. Other issues, such as a damaged clutch fork, can cause gear selection problems.

A worn clutch cover can make it difficult to select a gear. Most clutch covers have a sprung center section, which helps to control the friction plate. If this sprung section has weakened, gear selection can be difficult.

Crunchy reverse

If you are driving along and decide to stop and select reverse, you may find it crunches. You know what they say? If you can’t find it, grind it, but to avoid any damage, there’s a technique to help preserve your gears. Before selecting reverse, select second gear. This will help to slow down the layshaft inside the gearbox, making it less likely to crunch into reverse.

Other crunches in the gearbox

If you find the gearbox crunches when changing down gears, often into second, then this is generally no fault of the clutch. Instead, there may be worn synchromesh inside the gearbox. Sadly, if this is the case, the gearbox will need to be dismantled to fix this problem.

Slipping car clutch

A slipping clutch arises when the friction plate has become worn and it cannot provide sufficient grip onto the flywheel. Consequently, the power of the engine isn’t efficiently transferred to the gearbox. What usually happens is the engine sounds as though it is over-revving, and acceleration is slower than it should be. The friction plate will continue to wear, so it’s important to replace it. If you are inspecting a friction plate to see if it is worn, look for the rivets around the face of it. These should be inset, but if they are level with the surface of the friction plate, then it’s worn.

Noisy release bearing

With the engine running, press the clutch pedal down, then release it. Do this several times and listen for a noise that appears when the pedal is off and disappears when it’s down. This may be a noisy release bearing, which sits over the input shaft of the gearbox, close to where the clutch assembly is fitted. It can become dry, worn and consequently noisy. Replacing it is the best solution, but this involves separating the gearbox from the engine to access it.

Rattly dual mass flywheel

A number of diesel engines have a dual mass flywheel, which can rattle when it fails. The noise usually stops upon pressing down the clutch pedal. Replacing the clutch assembly is often quite expensive. Some people convert to a solid flywheel, but the dual mass flywheel helps to smooth out power delivery.

Removing a gearbox

The gearbox has to be removed or at least separated from the engine to change the clutch components. Draining the gearbox oil is often essential to avoid washing yourself in the stuff.

On most front-wheel-drive vehicles, the gearbox is fitted on the left or right side of the engine bay. There’s usually space to remove it after disconnecting the driveshafts. Gearbox mounts, linkage and mounting bolts that hold the gearbox to the engine (bellhousing bolts) will need undoing. Plus, the clutch will need to be detached.

On rear-wheel-drive vehicles, it may be possible to extract the gearbox from underneath. The propshaft will need to be detached, along with any mounts and bellhousing bolts. Plus, the clutch needs detaching, there may be a speedo drive cable and wires for the reverse sensor.

Changing a car clutch after identifying problems

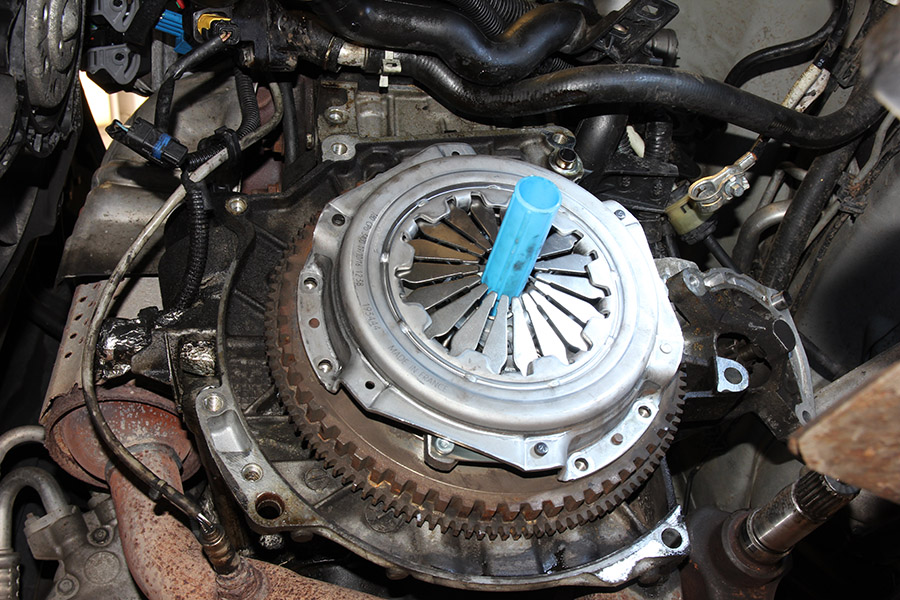

Most car clutch assemblies are attached to the engine’s flywheel with half a dozen small bolts. The clutch cover and friction plate will usually be fitted here. After removing them, the replacement clutch will need to be fitted with an alignment tool. This ensures the center of the friction plate is correctly positioned for the input shaft of the gearbox. You’ll only find out if it’s correctly aligned when trying to refit the gearbox.

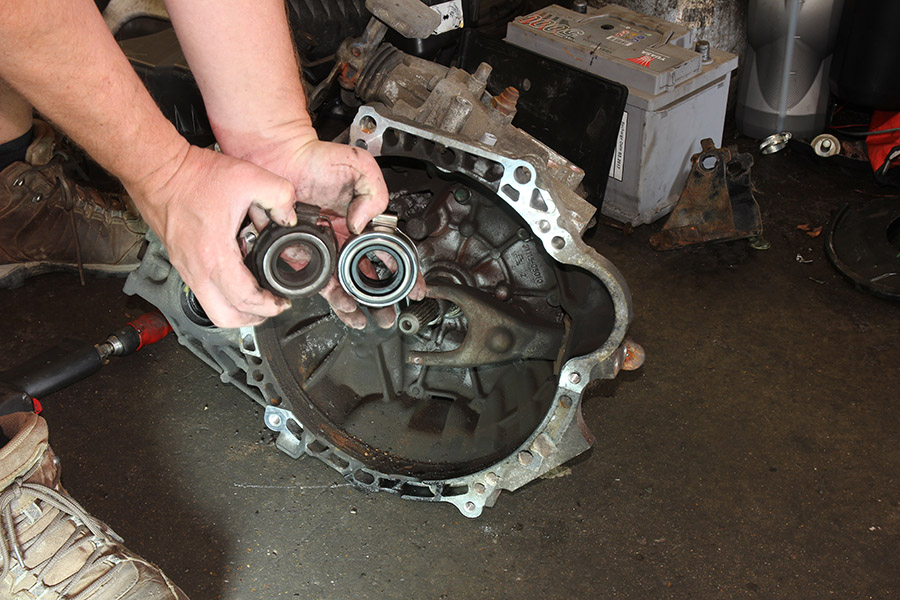

Fitting a new release bearing and possibly a slave cylinder are all completed from the gearbox. Inside the bellhousing area is where the release bearing is usually found, secured with a small bolt. And in some cases, the slave cylinder is attached to the release bearing and fitted onto the gearbox.

Our advice

Diagnosing car clutch problems isn’t always so straightforward. In some cases, it’s more economical to replace an entire clutch assembly and have peace of mind. In all cases, don’t ignore clutch problems. They won’t fix themselves.