Hot brakes work very well, but REALLY hot brakes don’t work at all. So, here’s our comprehensive car brake cooling guide.

Just like most parts of your car, brakes have an optimal working temperature, and while being under that level will lower braking efficiency, being wildly above it can cause serious issues to both their performance and your safety. This is where cooling comes in.

On the road, unless you’re an absolute lunatic, have terrible brakes, or an incredibly heavy vehicle, cooling generally isn’t an issue. But on track it can be a vital part of your setup, especially for continuous hard laps.

There are various ways to help keep your brakes cool, some obvious, some basic, some unusual, and some extreme. This feature aims to cover them all…

Bigger brakes

Sounds simple, and it is, but the main reason for bigger brakes is improved cooling rather increased braking power. Yes, larger diameter can help performance, but the main advantage of a larger surface area is for increased heat dissipation. A larger diameter disc will heat up slower and cool down faster, and as such is by far the most common upgrade for someone wanting to improve their brakes’ ability to cope with heat.

Air ducting

Increasing airflow to your brakes is the most common sense way to keep things cool, and it really does work. Almost all production performance cars have some form of brake ducting, and all race cars have in-depth ducting setups to maximize brake cooling airflow.

This consists of ducting from the front or underside of the car directly to the brakes, with some setups having an outlet that literally forces the air to hit the disc or caliper rather than simply head in that general direction.

As a cheap and easy DIY project, improved brake ducting can be done by anyone, but of course, the more high-tech and specialized air ducting setups can cost an incredible amount of money.

Wheel choice

The design of your wheels can have a surprisingly large effect on brake cooling, both due to letting hot air out, and cool air in. For air out, this is simply a case of having a more open wheel design, as things like steel wheels where there’s very few holes can trap heat behind them, increasing heat to unsuitable levels with hard use.

For airflow in however, while some wheels would help here more than others, very few will actively push air towards the brakes. The solution to this is turbofans, a flat disc with fan blades on the back which race and rally cars sometimes bolt to the outside of their wheels. These direct air in and towards the brake discs. While these days turbofans are mostly fitted to cars for cosmetic reasons, they truly do have a positive effect if designed correctly, and were very commonly seen on ’70s, ’80s, and ’90s race and rally cars.

Water spray

Ever watched truck racing or old footage of Audi Group B rally cars and noticed clouds of steam emanating from the wheels? That’s because they run a water spray system to cool the brakes. The concept is simple, you have a tank of water, a pump, and spray nozzles pointing at your brakes to keep them cool. How much you spray and how and when it’s activated will depend on the application, but it certainly is effective and has been used in top levels of racing and rallying for decades where rules allow it.

The main problem is it’s a total loss system, so unless you carry a huge amount of water on board, you may run out surprisingly quickly, therefore the performance loss from added weight may negate any improvements in brake cooling in some applications.

Water cooled

Yes, we know the ‘water spray’ section would count as water cooled too, but this is something totally different, as it isn’t a total loss system, but a conventional cooling like you would keep your engines temperatures in check. Water flowing through the body of the brake calipers and sometimes even through the brake master cylinder or a separate brake fluid cooler is a common way to keep temperatures down on race cars, especially on endurance racers where a total loss system just isn’t viable.

Of course this means you need to run specific brake calipers and so on to be able to achieve this, and we’re sure you don’t need us to tell you they have a very specific price tag to match, but if you want to run them, they are out there…

Engine braking

You know a good way to keep your brakes cool? Don’t use them! Seriously, while less common in racing and track use as people tend to have more of an understanding of performance driving, this is a very common issue on the road.

Ever see signs near a steep downhill section that says “Low gear for 3 miles” or similar? That’s because if you use engine braking to slow your car down, i.e. use a low gear so the car itself is trying to slow itself, you need to use the brakes a lot less, in many cases not at all. Vehicles sitting in a high gear controlling their speed by having their foot on the brake rather than using engine braking is the number one reason brakes overheat in road use.

Exhaust brake

Diesel engines, due to their lack of a throttle plate, tend to have less natural engine braking than a spark ignition (aka petrol/gas) engine. Because of this, an exhaust brake is sometimes employed. Working similar to a conventional throttle, but mounted in the exhaust system, when closed it massively restricts gas flow through the engine. That in turn increases engine braking to a huge extent.

Things aren’t quite as simple as blocking the exhaust, as of course it can only be closed when needing to slow down otherwise it massively restricts engine performance. Also, even when slowing, the amount it restricts is a balancing act between the maximum braking effect and reliability issues caused by huge exhaust backpressure. When working correctly though, exhaust brakes are one of the key factors that prevent the conventional braking system from overheating on heavy commercial vehicles.

Jake Brake

A final thing worth mentioning here is the closely related compression brake system, best known as a Jake Brake. This is a more in-depth system that’s integral to the engine’s internals, and when activated it vents the compression stroke of the engine directly in to the exhaust, allowing very little power to be transferred to the crankshaft. This massively increases engine braking, much more than a conventional exhaust brake.

The offshoot of this is noise when activated on the overrun, which while many enthusiasts love the noise, your typical person won’t appreciate. As a result, these systems are banned in many places in the USA!

Hybrid/EV regen braking

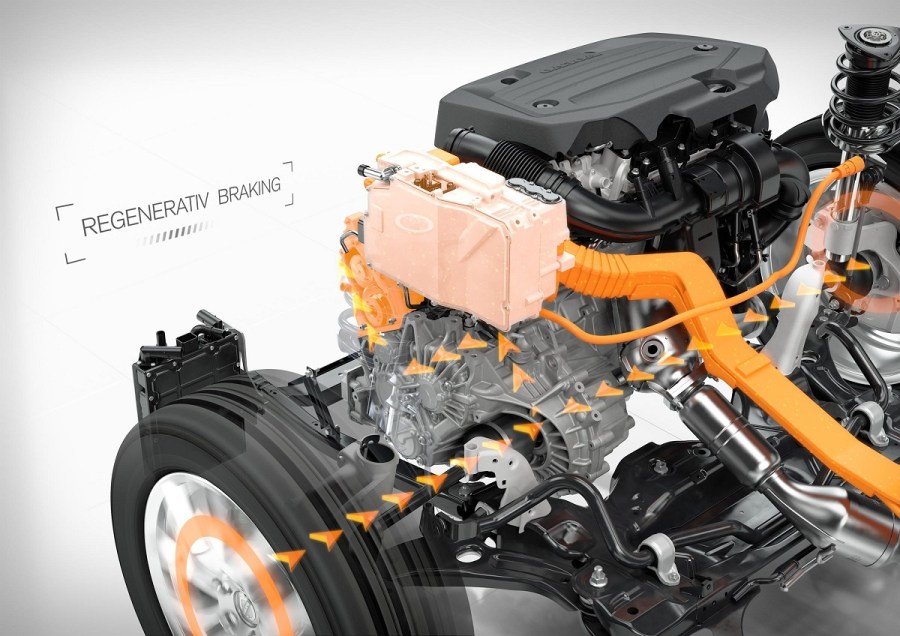

While we think of modern EV technology giving engine performance, it also has a braking effect on certain vehicles with regenerative braking.

Working much like a conventional engine’s engine braking system, it uses the engine itself to help slow the car, therefore putting less load on the conventional brakes. The added advantage of this is this system also works much like a dynamo or alternator, helping to recharge the batteries. Modern Formula One and other hybrid and EV race cars use this setup, so while it’s alien to most of us currently, we will all likely treat this as commonplace in the future.

Lighten your car!

One of the best ways to keep your brakes from overheating is give them less work to do, and the number one way to do that is make your car lighter. We’re sure you’ve all noticed heavier vehicles tend to have bigger brakes, but also tend to have much more brake overheating issues, and that is no coincidence. Weight is an absolutely massive factor, and even the best improved brake setups struggle to cope with heavyweight vehicles.

For this reason it’s common to see ultra light race cars run what look like pathetically small brakes, but with zero overheating issues. And on the flipside, this is why many heavy cars, even high performance standard production cars, have serious heat related brake issues within a very short period of time on track.

While all weight loss from a car is beneficial, lighter wheels and tires have the biggest effect for any given amount of weight saved, due to these being the components the brakes are actively trying to slow the rotation of.