When a dyno day ended with a bang, Ben Stirling took the chance to build his modified Shelby GT500 Mustang back faster, louder, and smoother than ever.

Millions of years of evolution have given us all built-in barometers for risk. With the needle set too low you’d never leave your bed, too high and you probably wouldn’t last very long, so most of us naturally hover somewhere in the middle, happy to hop on a plane every now and then or eat spicy food, but leaving free-climbing skyscrapers to a select few loonies.

Car folk have a similar risk barometer when it comes to dyno days. It’s fun to learn how much power your car is making, but most of us know there’s a chance the car might not leave the rollers under its own power. If your risk-aversion outweighs your curiosity then you’ll probably give it a miss, while others will happily spend hours at the dyno subjecting engines and transmissions to dozens of pulls to find that extra horse or two.

Blowing the original engine

Nobody really expects their car to go up in smoke though. Ben Stirling certainly didn’t expect to be in the firing line as the catalytic converters in his Shelby GT500 exploded during a dyno day at Torque Developments in 2021, and fired scalding blobs of molten metal past him like hazardous obstacles in a Mario Kart level.

“I was standing behind the car and have the whole thing on video… all the exhaust was coming through one side of the twin exit system, to the point it was physically blowing over their metal vacuum, and then BANG! I was just engulfed in smoke, and then these bits of molten metal flew past…”

As it turned out, the cats had melted, building up exhaust pressure to the point that the remnants had only one way to exit. After a quick check to make sure he wasn’t full of smouldering holes, attention then turned to what might have caused the cats’ rapid unscheduled disassembly – but surprisingly, the engine itself wasn’t in such bad shape.

“They started looking into the engine and could see from the spark plugs that there must have been a small compression leak, and suggested they do a compression test. And it all kind of started from there, as I wanted to make sure the engine was okay. So they took the engine out, and did a full check.”

Rebuilding the engine in the Shelby GT500

If you’ll pardon the pun, it wasn’t just the firework show that served as a catalyst to rebuilding Ben’s GT500, so we’d better go back to the start, when he first bought the car as a lockdown purchase (how many of us have been there and done that?) during 2020.

“I had a Mustang GT at the time, but I wanted to get a GT500, because it felt like the last of the big muscle cars – manual, big power, live rear axle. I grew up watching Dukes of Hazzard and Knight Rider, so I’ve always had this obsession for American cars. Anyway, I wasn’t allowed to go and see it, as we were all in lockdown, but after watching about fifteen video tours of the car and seeing it from every angle, I decided to go for it.”

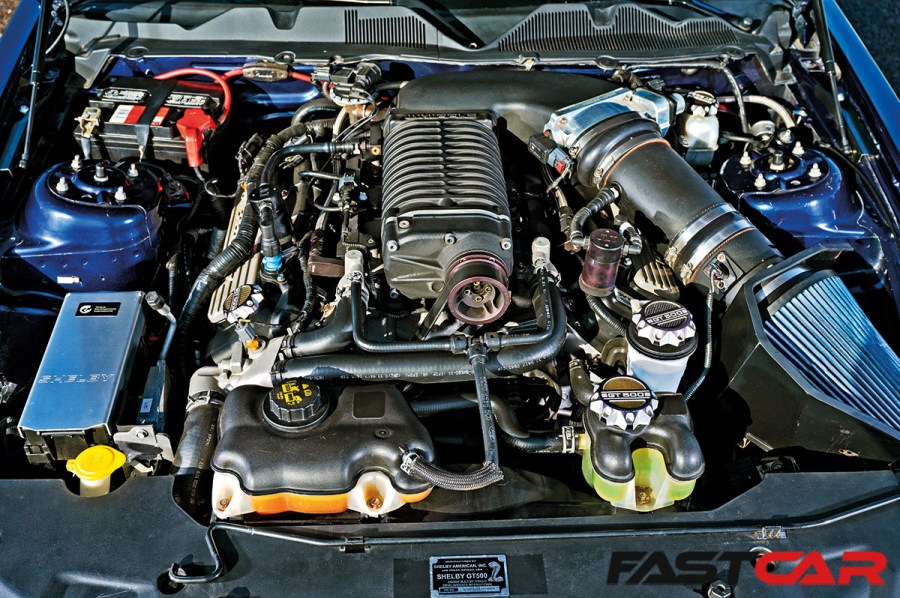

A recent import, the Shelby GT500 was claimed to be making around 750bhp – up from the factory 540bhp. “And I went sideways on pretty much my first trip out!” Ben laughs. “It was very different from the GT. SVT gave it a huge amount of extra mods, more power, stiffer suspension, and then this one had a fair bit done to it as well. I think it’d probably done some drag racing in the US, as it had a line-lock fitted, different rear suspension, a 2.9-litre Whipple supercharger, and an upgraded fuel system. The first drive was pretty scary!”

Not making power

Ben wanted to verify the horsepower claims on the badge though, hence the dyno day. And even before the spectacular conclusion, things weren’t going quite as expected. “The engine was hitting 500-and-something and then pulling power, and the line on the graph was like a zig-zag. So they decided to do another run…”

Fast-forward to the other end of the day’s events, and a check of the engine revealed that though it was largely in one piece, one of the exhaust headers was cracked, and while all the pistons were still piston-shaped, they were showing signs of excessive wear, and likely all bleeding compression. So Ben gave the green light for a rebuild: in went forged pistons, forged connecting rods, and new fuel, water and oil pumps. The crank and flywheel were both balanced too, to around 0.75 of a gram away from perfect. “I think it comes out of the factory at four-plus grams out of balance, so under a gram is pretty amazing,” he says. “You can balance a coin on this engine and it doesn’t even vibrate.”

New parts for the Shelby GT500 Mustang

Several parts from the later 2011-on GT500 also went in, along with a lighter, larger, lower supercharger pulley, though the ’charger itself, already a sizeable unit, was deemed more than suitable for hitting that 750 mark. As is the exhaust system, with a set of 3” American Racing headers, feeding a custom valved exhaust from Overkill Performance in Milton Keynes. “I can run it as an open pipe,” says Ben, “and the response is amazing. Or I can run it with the valves closed, which is my ‘friendly neighbourhood’ mode! It’s a McLaren valve, and good for about 800 horsepower, which is what I needed it to be able to handle.”

It was a slow process, as these things often are. “At that point I think I’d had the car for a few months, and they had it for the best part of year!” says Ben. But when the car finally came back, along with an archive of photos of the rebuild, it was a Shelby transformed.

“The engine was much more responsive, and with much less vibration… there wasn’t a lot of vibration before, but you could tell it was running really nicely.” A more aggressive clutch took a little getting used to, but that was more than made up for by the response – something Ben credits in part to that Overkill exhaust. “The standard system goes down to a 2.5” pipe and then over the rear axle, but in classic Ford fashion they didn’t curve it over, they just bent the pipe, so it probably goes down to an inch in places!” At three inches the whole way, there are no such problems for the new system, though Ben reckons it’s lost a bit of the old loping idle. “It almost sounded like it had hot cams before, but I think that was just the air trying to get out…’

Conclusion

There’s a little more work to be done with cooling – an engine like this produces a lot of heat, and those running similar setups in the US have found their power drops off somewhat after a run up the drag strip – but the plan now is simply to drive it. After the risk of putting the car on the dyno, the risk of being showered with hot metal, and the risk to his bank account, Ben deserves the reward now, don’t you think?

Words: Antony Ingram. Photos: Jason Dodd.