You can make a lot of progress on a project over ten years; Forest Benner has taken his modified VW Rabbit Pickup to the next level…

How many of us can think back to our first modified car and, looking past the ghastly parts choices, smile at our tuning accomplishments? How many of us are still at it with that same vehicle over a decade later?

I know this embarrassed author was super proud at the blocky ‘BORA’ badge he stuck to the trunk of his Mk3 Jetta, only to replace it years later with a proper Vento appliqué upon completion of a full Euro overhaul. The shell of that car is languishing in a Massachusetts junkyard somewhere, if it hasn’t been crushed already. Regardless of our regrets, our juvenile choices helped guide and mold us into the enthusiasts we are today.

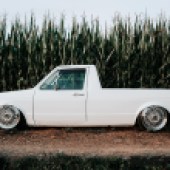

Forest Benner, a 29-year-old caulking professional from Middleburg, Pennsylvania, has owned this 1982 modified VW Rabbit Pickup since 2012. “I originally took a liking to diesel Rabbit Pickups when I was around 16,” says Forest as he’s recalling his origin story. “I thought it was ‘cool’ that they were mini trucks that could ‘roll coal.’ Living in the country, diesel pickups were all you saw,” says Forest.

For those unaware of the existence of the half Rabbit, half hauler before you, allow us a moment to provide some background. In the late 70s, Volkswagen took over an abandoned Chrysler factory in Pennsylvania to use for their efforts to join the burgeoning small truck segment in the US. The Rabbit Pickup was introduced to the North American market for the 1979 model year and sold in mediocre numbers through 1984. Sales weren’t as great as expected and the Rabbit Pickup didn’t continue in the US past the introduction of the MK2.

Despite the Westmoreland factory where the Rabbit Pickup was built being just a three hour drive west, it took Forest approximately two years to find the right one. “I believe the exact day I brought it home was September 7, 2012,” he estimates. “Everything snowballed from that day.”

Recall the aforementioned statement about adolescent tuning tastes? “My ‘modding career’ started pretty much right away,” Forest enthuses. “But it didn’t start with the initial build.” He goes on to admit sanding the paint down to give it that rat look that was never popular at the time, as well as employing Racelands with an axle flip and drop plates for the stance and Klutch SL1s for the poke. Despite those newbie mistakes, err choices, Forest was still having a good time.

“During this time I met a few friends that had Mk1s,” says Forest. “Gage Seyfert, Cory Lape, and Cole Martin; we all shared the same passion. [We] cruised almost every weekend and worked on our cars. I learned most everything from those guys.”

Inspiration can be drawn from a multitude of sources. Whether it be flipping through your favorite VW tuning magazine, scrolling your social media channels, or in Forest’s case, attending a show and absorbing your surroundings and sightings. “H2Oi 2013 was the turning point for me,” recalls Forest. “After the weekend in OCMD, I knew I wanted to start the build.” So it was in December of 2013 that the pickup was temporarily relocated to his parents’ garage.

“The original plan was to throw air under the truck, nice wheels, and a home paint job,” Forest chuckles. “It didn’t come close to only that.” This a tale no doubt all too familiar for many of our readers. However, despite mission creep clearly taking over the controls, progress was continuously being made. “I pulled the 1.6 out to paint the bay,” says Forest. “While in the bay, I started to cut a few unwanted tabs out. Then…well…I shaved everything.” Remember folks, if you or anyone you know has a shaving addiction, you don’t have to suffer alone. “My father was there to help guide me. He did most of the exterior body work, and there was a lot of it.”

Some people know from an early age they want to become a doctor and work their entire life to achieve the white coat. Others take it one day at a time, relying on guidance from the universe to help with their decisions.

“As far as knowing what I wanted and styling,” Forest goes on to say, “I had some ideas of what I wanted, but I think I changed my mind 17 times along the way. The color was going to be Forest Green (that sounds a bit self-indulgent – author). My girlfriend at the time, Breonna, now wife, highly encouraged white. So white it was.” Forest continues, “I then knew I wanted a chrome/white everything theme. I was going to use the 1.6d and paint/chrome everything. The reality of having a clean shiny diesel in a white bay just isn’t there.

I decided I wanted to do a gas engine. Every VW engine went through my head. My good friends recommended an ABA. The goal was to do the most simplified ABA out there. But all in all, it was fly by the seat of my pants the entire way.” For what it’s worth, Forest didn’t grow up with an automotive background. His only real mechanical experience was from racing motocross for a few years and wrenching on his own bikes. Otherwise, it was learn and be learned the entire build.

Over the course of the next three years, Forest had continued to work on the Caddy. “Looking back I wish I would have made a rotisserie,” Forest muses as he reflects on the challenge of not having a lift. “Keep in mind I did everything with the pickup on jack stands,” says Forest. “I spent hours upon hours cleaning off the old undercoating on the inner fenders and also the carpet glue. What an experience.” All of a sudden the three year investment of time doesn’t seem unreasonable. But it wasn’t 1,095 days of a singular focus. Forest also divided his attention on the engine itself, sending the head out to get polished and having miscellaneous pieces chromed, among other work. “Those things take time.”

At this point it’s important to mention the timing. For anyone who hasn’t built a car, or overseen the construction of one, it’s not unusual for things to get drawn out over years. “A few months at a time went by just because I didn’t know what direction I wanted to go,” admits Forest. “What to chrome, what to paint. It ended up basically chrome or polish everything that could physically be chromed or polished. Anything that couldn’t was painted or powder coated white. That process took years.

There were parts that I had made, then would decide to go a different route. I felt like a was going in circles the entire eight years I was building it.” Timelines also have to be shared with all of those involved, and often a delay here leads to one there. Patience is a must, especially if you’re hoping to stick to some sort of budget.

It was 2016 and the Caddy was in primer and ready for paint. Forest had also installed the Seen-It 4-link rear suspension by this point. “I sent the pickup to R Miller Auto around March of 2016,” says Forest. Ryan there made sure the body lines were razor sharp and expertly laid down the Honda Grand Prix White, including spraying the brake booster. He also removed the fuel filler door and relocated it to inside the bed, a detail that can be easily overlooked but one that Forest is keen on. And three cheers for not switching to single rounds up front.

Not one to squander downtime, the interior bits, including those beautiful Recaro Trophies, were taken to Dressler’s Upholstery shop for their moment in the spotlight. “The hex tweed just came to me one day,” beams Forest. “I’ve always loved the look and feel of tweed. I looked at [Dressler’s] color/material samples for hours. I think I always knew I wanted to use that peanut butter color pallet. Dressler definitely executed it perfectly.” We would agree with that sentiment. Other notables include the CAE Motorsports shifter polished by NBP Finishing and BBS steering wheel wrapped by Swift Stitch Upholstery. The Racepak iQ3s cluster is set in a custom brushed bezel also by NBP Finishing.

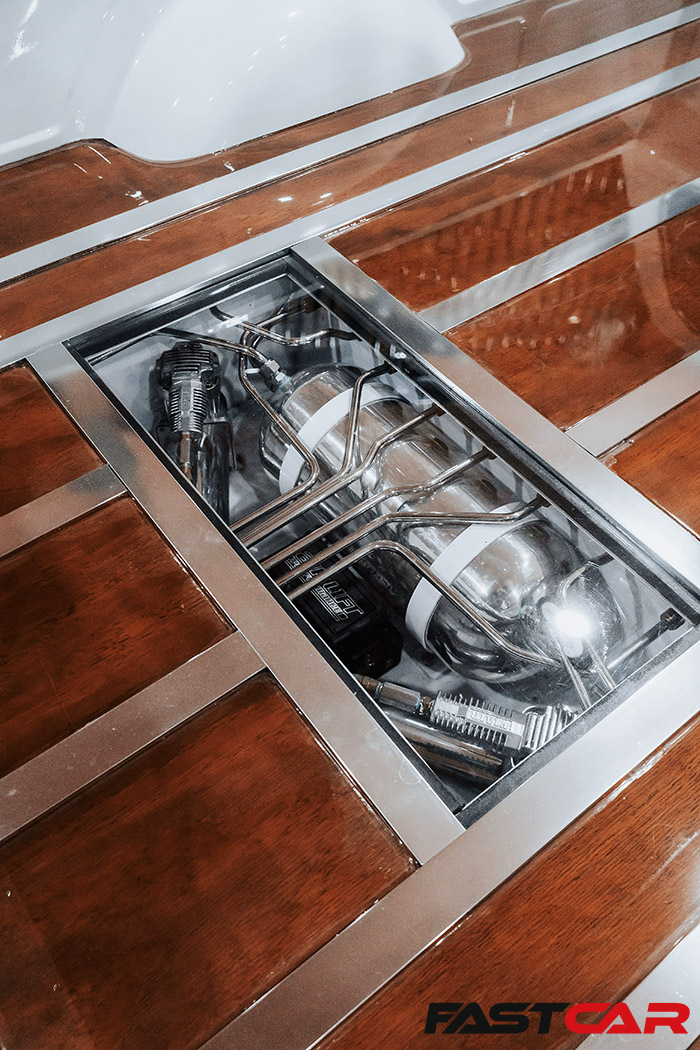

Once the modified VW Rabbit Pickup was back from paint, the slow process of reassembly began, continuing for another three years. “Waiting on parts, changing parts, changing my mind,” says Forest. “Slowly but surely I kept picking away at it.” The bed project was one that tested Forest’s patience, as well as furthered his skill set. “The bed floor wasn’t in the best shape before I started the wood idea,” says Forest. “I think the uneven surface made it challenging for me. I had to notch the back of the wood in some spots and getting the cuts perfect was challenging for me as well. The combo between the wood and air ride box was just something I struggled with. I didn’t have any experience in either of those departments. For sure the hardest thing for me was those stainless lines. Getting them to line up with the push-to-connects was awful. I made it work though. I finished it off with a clear epoxy resin on the wood. I wanted a glass like look.” With the interior finished in 2018 and the recessed air tank and bed wood project completed in October of that year, finishing touches spilled into 2019.

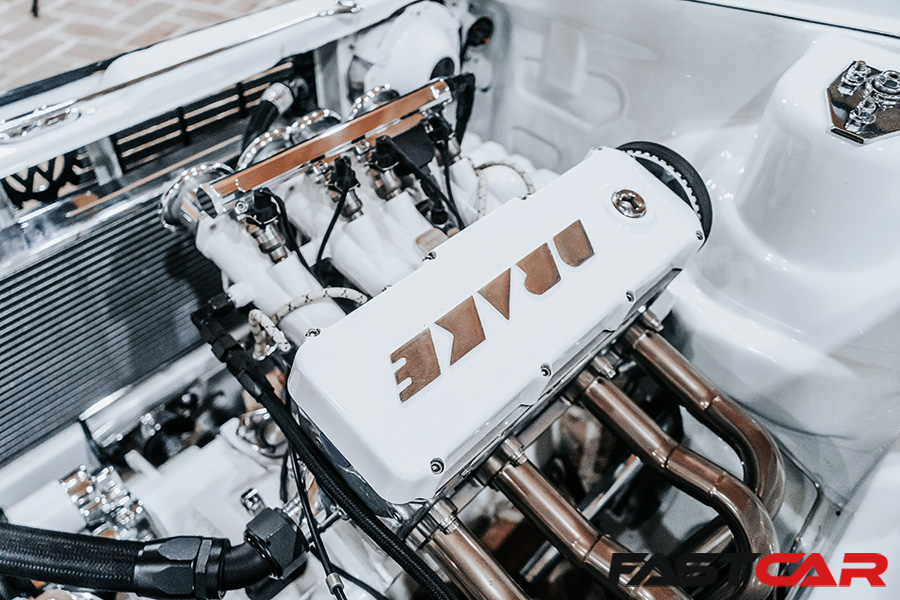

In May of 2019, the truck was sent off to someone many of us are familiar with – Matt at Eurokraft – to take care of the wiring, as well as bringing the motor to life. “One year later he sent me a video of the engine running,” smiles Forest “[It was] music to my ears.” Let’s pause a moment to really study that engine. You’d be forgiven for not being able to identify its ABA roots. Out back, the exhaust manifold is the artistry of Swoops while the ITBs are Borlas. The crown jewel of the bay is the Drake valve cover, one of allegedly four in existence.

It was sourced and powder coated by Frank Clarici of Shore Polishing and Finishing, another name associated with a fair share of feature cars. Attached to the motor is an 02A trans, although that wasn’t originally the plan. “I was going to use the 020 trans I had,” says Forest. “It was all painted up ready to go. Then my buddy Cory had a 02A trans for sale that I bought. I figured it was better suited for the ABA. I had that split apart at German Diesel Motorwerks, sent the cases to get powder coated, and back to GDM to get rebuilt.” A hydraulic clutch kit from Fast Bunny Metalwerks assists the cog swapping.

Once the modified VW Rabbit Pickup was picked up from Eurokraft, it took another few months to get the suspension dialed in. There are modified Mk3 Air Lift front struts to complement the 4-link rear, all controlled by Air Lift’s 3P management. All conspire to allow perfect placement in the arches for the BBS E48s. The Caddy wasn’t always rolling on the center-lock magnesium wheels though. “When I had first started the build in 2013, the trend was fender sitting on wheel lip with gnarly-ass stretched tires,” jokes Forest. “That’s what I was initially going for with my 15” RSs. Time went on and I saw a few Mk1s popping up with 17s. I wanted to tuck 17s, so I searched for company’s that made step lips for 15” RSs. Wheel Flip had what I needed. I finished the build with those wheels and had those on till July 2021.”

Anyone with half an ounce of dubbing in their blood will be able to see those aren’t the RSs Forest just gushed about on the Caddy. “Those wheels were too wide and I had too much camber going on. My style had changed a bit.” Enter the zero-lipped E48s, tucking just as good as the former hoops, but, as Forest thinks, are more period correct.

With everything just about sorted, it was time to enjoy the fruits of eight years of labor. “I was “kind of” done in time for VAG Fair 2020,” relishes Forest. “It wasn’t 100 percent complete, but I showed it anyhow. It was missing some tail light screws, headliner, and some small bits. Cory Sterling talked me into coming. All in all, it was the crowd favourite which really put a smile on my face. It won Best Engine Bay and 3rd Best of Show. I was pleased considering it wasn’t totally complete.”

From there, Forest attended MK1 Madness in 2021 and scooped up the Best in Show and Best Rabbit Pickup awards. In Helen, GA, the Caddy was a Top 10 winner. It seems to be a magnet for medals. “I’ve gotten very good feedback these past two years,” enthuses Forest. “The VW/Mk1 community is full of great people.”

As usual, we sign off asking what the future holds for the feature vehicle, as project cars are either almost never done, or passed along to make room for the next project. “I can’t say I ever see myself parting with the Pickup,” Forest steadfastly says. “As for now, I will continue to drive it and attend some shows and enjoy it with friends and family. I won’t say too much, but you may or may not see another Rabbit Pickup build from me in some time. My wife and I just had our first child (Kove Calloway) so we are a bit occupied loving on him!” Perhaps in the future we’ll see a miniature version for the little man to cruise around in?

Feature from Performance VW magazine. Words: Bryan McCarthy. Photos: Pat Roell.

Tech Spec: Modified VW Rabbit Pickup

Engine:

2.0-litre ABA 8v with TT 276 cam, TT big valves, Swoops headers, Fresh Reflections radiator and catch can, 02A five-speed, lightened flywheel, Drake valve cover (1 of 4 in existence), Borla ITBs, Megasquirt Microsquirt stand-alone, engine simplified as much as possible, all wiring done by Matt at Eurokraft Performance, all chrome and polish done by NBP finishing and Shore Polishing and Finishing and 4 Ever Kustoms

Chassis:

BBS e48 center locks with BBS Motorsport 0” lips, Momentum Motorparts 10.1” Wilwood brakes, Air Lift Mk3 front air struts modded to fit, Seen it! 4-link rear suspension, Air Lift 3P management, visible box in bed with tank and compressors and home-made hardlines

Exterior:

Painted Grand Prix White (S2000/NSX white) painted by R Miller Auto Body, shaved fuel door relocated on inside of bed, bed floor wood topped with clear epoxy, shaved bay with shaved fender hardware done by me

Interior:

Recaro Trophy seats wrapped in leather/tweed, early Westy dash leather wrapped, Racepak iQ3S cluster with custom bezel brushed, seats/dash/interior done by Dresslers Upholstery, BBS 3-spoke steering wheel wrapped by Swift Stitch Upholstery, custom horn button made to accept BBS 70mm cap made by NBP Finishing, CAE Motosports shifter polished by NBP Finishing