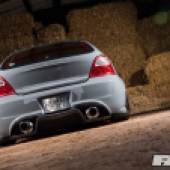

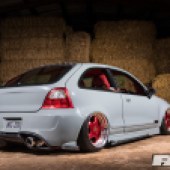

Built by one man in a barn on a Welsh farm, this modified MG ZR has evolved from bone-stock diesel plodder to flame-spitting show car. Dan Pritchard’s DIY project is the definition of ‘built not bought’

History is studded with examples of self-taught everyday heroes. People who, despite having no formal training in whatever it is they’ve decided to set their mind and their hand to, simply get on with learning how to do it on their own terms. There’s no whining, no histrionics – they merely identify a gap in their knowledge and attempt to fill it. People like Chris Gardner, protagonist in the biographical tale played by Will Smith in The Pursuit of Happiness. The doomed but plucky Frank Grimes in The Simpsons. And, of course, Dan Pritchard – intrepid MG ZR owner, who learnt all of his skills in carbon-fibre fabrication, bodywork design, paint spraying and air-ride installation, simply by googling tutorials and watching instructional YouTube videos. As the flawless results before you demonstrate, he’s evidently a keen and patient learner.

It all began impressively early, too. “Ever since I was a young lad I’ve always been fascinated with cars,” he says. “I remember at the age of 15 sitting outside Woolworths with my mates reading Fast Car, in awe of the cars, thinking how lucky the owners were. As soon as I passed my test I bought my first car, a Renault Clio 1.2. A few months later came the release of Fast and Furious. From this point on cars took over my life.

I started to modify the Clio and boy were there some harsh lessons! I started smoothing things off with filler, with no idea what I was doing. This was before the days of YouTube, so I was just guessing. I soon destroyed this car to be fair, as it was covered in filler and a lairy bodykit. But I enjoyed it so much I didn’t care how bad it looked.”

Admirable sentiment. And it’s this tenacious self-taught ethos that informed the future direction of Dan’s modifying adventures. Learning by doing is key to so many things in life; you should never regret your mistakes as long as you learn from them. And Dan was all over this. “These days people at shows always ask me ‘How do you know how to do so much on cars?’ But the truth is I’ve not always been so handy,” he laughs. “The Clio was where I learnt how not to modify.”

It was while this early project was going on that Dan met Steve Pearcy, a fella who went on to become a great mate and modifying buddy. Steve raced a Rover in the Welsh Euro Saloon Championships, and the shouty turbo thrills pushed Dan onto the Rover bandwagon. Before long he had a 214si, into which he shoved a 2.0-litre turbo motor. After experimenting with modding a bunch of Golfs, Dan took his keenness for Rovers to its logical conclusion, buying himself an MG ZR in 2010. (Which, of course, is effectively a tarted-up Rover 25.)

Bought as a sensible daily smoker, the turbo-diesel ZR was scratched to all hell and not run as an object of pride – it was there to fulfil a purpose. And yet, with those modding aspirations ever-present, the ropey aesthetics were starting to grate on Dan’s sensibilities. He started by converting it from Mk1 to Mk2 spec, which contemporised the looks, but also highlighted how keenly it needed a respray – so he decided to just do it himself in Frozen White. As you do.

“That’s when the project really started,” Dan says. “After 15 months of daily use I was bored of the diesel motor. I still had the T-Series turbo engine from the old project so with Steve’s encouragement I dropped it in. Although in taking the car off the road, it stayed there for four years.

“I didn’t intend for it to take so long. But things just started to spiral out of control and I got carried away. Rather than just a straightforward engine conversion, I wanted to smooth the bay and make it look nice. This took way longer than anticipated and I ended up having to buy myself another vehicle to use for work.”

This, naturally, meant that Dan was in no rush and could take time to do the ZR right. And that’s exactly what he did. The 2.0-litre motor was rebuilt with stronger internals, a Garrett GT3076R and a screamer pipe, along with all sorts of other go-faster goodies. Having got the hot engine into the smooth bay, the finish was in sight. But then Dan discovered the magic of carbon-fibre.

All bets were off, having taught himself how to hand-craft carbon-fibre (yes, seriously). Suffice to say, carbon become something of a theme for the little MG.“I did get a bit carried away with that,” Dan grins. “And with the exterior looking better, I had to do something about the interior. I set about totally changing it, and now I was getting handy with the carbon fibre I decided to start splashing some inside the car.

“I made a custom dash, significantly changed from the original dash shape, made using the bare carcass and some fibreglass to shape it. The centre feature of the dash is an iPad which acts as the headunit to the audio install. Next I made doorcards to match the dash, and in the rear I decided to strip out the back seats and create a boot build with custom carbon-fibre sub enclosures and a false floor.”

Being a regular show attendee, Dan knew he wanted air-ride for the MG, and unsurprisingly it’s not a model that’s catered for by off-the-shelf kits. So you can imagine what happened next, can’t you?

He did a bit of research to see how it was all constructed, then he made his own struts, plumbed in the air-ride himself, and the job was a good ’un. And then he covered everything in custom home-made carbon-fibre. Obviously.

The snowball effect continued as Dan realised that, with the car aired out and a wide set of RH ZW1 wheels in the garage, his arches needed a bit more girth. The first thing he did was to get wider lips for the wheels (but of course).

And then set about building the bodywork around the wheels. “With previous experience of composite materials and bodykits, I knew I didn’t want to use fibreglass,” he says. “I wanted to make full metal wide arches, which would be more durable.

“After several trips to the scrap yard I decided to use Mk4 Golf front wings to make my car wider, and I got busy welding them on. I also rounded off the inner arches to allow full drop and still roll on 10-inchwide wheels, which was a great achievement! These new arches caused a knock-on effect, meaning changing the bumpers and re-thinking the side skirts as I needed to make everything 3-4 inches wider. I built my own parts such as the rear diffuser, made from scratch and based on the Jaguar F-type design. The rear bumper was built around the diffuser and then widened to meet the arches. The front bumper was modified significantly, adding DRLs and Audi R8-inspired grilles and lots of smoothing and re-shaping. I made a splitter from carbon-fibre, and followed on this look with custom sideskirt aprons and the rear vortex spoiler.”

What’s most astonishing in all this is that Dan makes it sound like it’s all in a day’s work. There’s no whingeing about cost or complexity. He just decides what he wants the car to look like, then teaches himself how to do it. It’s impressive enough that it’s not a huge mess. What’s incredible is that the quality is so consistently flawless. When he decides to do something, Dan just gets on with it. Take the recent colour change: four years into the project, he decided that the car should be grey. Having sized up Audi Nardo and Ford RS Stealth, his girlfriend Brooke suggested Ferrari Grigio Medio. And that was that.

“This Fast Car feature has to be the pinnacle moment for me, as it’s always been a goal of mine to get a car in this magazine,” he says. “I’ve learnt a lot over the years from welding, painting, engine work and carbon-fibre. People say, ‘Why do you waste so much money on cars?’ But to me it’s a hobby I’ve thoroughly enjoyed, and have no regrets spending most of my spare time working on it.”

And that’s the crux of the matter. He did it because he wanted to, and because he taught himself how. The very definition of the self-taught everyday hero.

TECH SPEC MG ZR

STYLING

Ferrari Grigio Medio respray (inc. underbody); carbon fibre skinned roof; custom carbon fibre rear vortex spoiler; full one-off metal wide arch body, extended 3in each side, built around the wheels; bigger inner arches to allow rolling on full drop; side repeaters smoothed off; custom front bumper, standard indicators and fogs smoothed off; new subtle LEDs custom-made inside grilles; bumper widened to meet new arches; larger mouth for more air into intercooler; custom R8-style grilles; DRLs installed perpendicular to grilles; bumper extended 2in lower with custom carbon-fibre splitter; de-badged, custom rear bumper – widened and side shape changed to meet arches; square numberplate recess; carbonfi bre diffuser (Jaguar F-Type style); carbon-fibre side trims made to match custom skirts – extended 2in lower, built around custom carbon-fibre lower section flared out 3in to meet new arches with race-inspired aero fi n; carbon-fibre detailing on door pillars; screamer pipe trim; fuel filler neck and inner wheel liners; carbon-f bre wing mirrors with indicators built in; various LED illuminated areas on exterior inc. under-car LEDs; illuminated intercooler and LEDs inside diffuser; modified Mk2 ZR headlights with retrofitted bi-Xenon projector lenses and dual angel-eyes; custom carbon-fibre headlight duct in passenger headlight; customised AutoArt rear lights; carbon-fibre skinned wiper arms; tailgate de-wipered with custom carbon-fi bre bung.

TUNING

Rover T-Series 2.0-litre 16v turbo; forged oversized 86mm Arias pistons; steel H-beam conrods; big valve head, ported, stage 3 Kent cams, updated valve springs, solid lifters, and Vernier pulleys; DTA S60 standalone ECU; 660cc Siemens injectors; ARP main; head and conrod bolts; Garrett GT3076R ball-bearing turbo; custom tubular exhaust manifold with 38mm external wastegate and front side-exit screamer pipe; Kevlar clutch and lightened flywheel; K&N Group A Cosworth air filter; HKS SSQV blow-off valve, large R34 GT-R front-mount intercooler (painted black with stencilled ‘ZR’); custom alloy rocker cover, Magnecor race HT leads; subtle black Samco hoses; 2x 13in Kenlowe fans with standalone thermostat; converted to later wasted spark ignition; custom intercooler pipes (covered in carbon-fi bre); engine cleaned and painted; Candy Apple Red gearbox; custom carbon-fibre timing belt cover; full custom AMW Motorsport exhaust system – 2.5in turboback, custom carbon-fibre covered driveshafts; AFR gauge; SARD fuel pressure regulator and gauge; Gizmo electronic boost controller; Bee-R anti-lag/ rev-limiter kit; external Bosch fuel pump and inline filter; swirl pot and braided lines; fully smoothed bay with engine components relocated; wiring loom extended and re-routed inside car with fusebox/ ECU behind dash; power steering under driver wing; ABS removed; brake lines hidden under car; engine bay fully laminated in real carbon-fibre; custom 1/5 carbon-fi bre bonnet to show off bay, custom carbon fibre strut top caps; scuttle panel under windscreen; carbon-fibre panels in bay to hide some components; PG1 gearbox with limited-slip diff and Dark Ice Designs short-shifter.

CHASSIS

9x17in (front) and 10x17in (rear) RH ZW1 two-piece wheels with Candy Red centres and stencil work, wider lips, gold bolts and custom Porsche centre caps; 25mm (front) and 15mm (rear) spacers; 215/40 Yokohama Parada Spec II tyres; custom air-ride system, Air Lift V2 management; 2x Viair compressors, 1x 4-gallon tank and 1x 5-gallon tank; custom etched MG logo inside dummy hard lines with built-in LED illumination; polished 6-pot Tarox callipers with 355mm 2-piece discs; custom engineered camber shims on rear; custom front top mounts; rear axle/disc brake conversion; fully polybushed; uprated Dark Ice Designs rear anti-roll bar; OMP strut brace.

INTERIOR

Custom carbon-fibre dash with iPad centre console and extra 7in TV in dash centre; top section added in flocked red to reduce glare; Sparco half suede/ half leather steering wheel and snap-off boss kit; custom carbon-fibre door cards – reworked in new shape with DIY speaker pods painted Candy Red with stencils; custom tailgate build with component speakers; 7in TV displaying rear view camera for shows; Recaro Trendline seats (from Honda Accord) re-trimmed in red leather with custom carbon fibre back panels and custom Recaro stencil work; stripped rear with carbon-fibre everywhere; custom carbon-fibre boot build inc. carbon-fibre floor (with MG pattern in weave); square sub enclosure; opposite amp rack/hidden battery box; air-ride install; tank mounts and caps; custom carbon-fibre switch panels in glovebox; custom A,B,C pillars flocked red with triple gauge pod smoothed into driver A pillar; diamond-stitched leather headlining; red Rover BRM carpet with custom red mats; flocked black centre console with modified switch arrangement; heater controls relocated behind iPad; Plasma dials; various LED illuminated areas inc. air-ride install.

AUDIO

iPad as headunit; Kicker 12in square sub in custom carbon-fibre enclosure; Kicker KX1200.1 monoblock amp with bass switch on dash; 3x pairs In Phase component speakers in front door cards (2x 6.5in, 1x 5.25in) in custom Candy Red speaker pods; 5x7in In Phase coaxial speakers in custom pods in rear door cards; 5.25in In Phase component speakers in tailgate install; 2x Kenwood amps hidden under false carbon-fibre floor; car runs Google Chromecast wifi (or HDMI converter in non-wifi areas).

THANKS

Steve Pearcy (owner of Grove Farm Garage) where I store and work on the car – he’s been a good mate for over 12 years, and it’s safe to say he’s taught me pretty much all I know about cars. I wouldn’t have done half the stuff I’ve achieved with this car if it wasn’t for his sharing his knowledge and experience; I would like to thank Jeff Williams (Williams Motors) for allowing me to use his bodyshop facilities whenever I’ve needed, as without him I wouldn’t have got this far in the project as I have – I thoroughly enjoy at least one week a year painting my cars and it’s a nice holiday break from my daily job in construction; Julian Rowlands for his metalwork skills, as he’s helped me throughout the build when I send him AutoCAD sketches of things I need cut with the CNC/Leith he’s always managed it; Tony at CAM Engineering, for showing me how to TIG weld and helping me create some of the parts on this car, like the manifold; Davy at Outlaw Racing, for all my graphics / vinyl cutting which allowed me to do all my stencil work. No matter what the request he was always able to help. And Rhys Lougher for allowing us to use one of their barns to shoot the car at Ty- Tanglwyst Farm.

Words Dan Bevis Photos Daniel Pullen