From being a vital engine component at best, to totally destroying your engine at worst, we teach you all you need to know about engine belts as part of your car maintenance knowledge.

One of the simplest yet most important components on any engine, drive belts perform a multitude of tasks and come in various shapes, sizes, and materials. While they are generally reliable and maintenance free, issues with them in any form is truly something you want to avoid.

What do engine belts do?

The two main uses for drive belts are to run your engines ancillary components such as your alternator and power steering pump, and as a timing belt on the engine itself to turn the camshafts. Either use of the belt having issues is not good news and you should stop driving immediately, but more often than not a timing belt issue will cause instant and catastrophic engine damage, so these are components that should never be neglected.

In this feature we’re going to give you a run-down on what these parts all do and the differences between the various designs. Without further ado, it’s our engine belts guide.

Rubber timing belts

This is the most common of all engine belts on a modern car. It’s used on the majority of overhead cam engines, but has also been used on some pushrod engine designs, especially as an aftermarket conversion. Also known as a cam belt, which hints at its main purpose, this is a toothed reinforced rubber belt that links the engines crankshaft to the camshaft(s).

The belt’s job is to turn the camshafts at the correct time and speed in relation to the crankshafts rotation. This in turn opens and closes the exhaust valves at the right moments needed for correct engine operation.

These belts can also run the engine’s water pump. However, depending on the design, this job is sometimes done by a separate belt or directly off the engine. They also use some form of tensioner, usually a spring loaded or hydraulic pulley that pushes against a part of the belt.

While simple, reliable, quiet, and low cost, it is a service item that generally is required to be changed every 60,000 miles or so depending on the engine. Being of a rubber design, contact with foreign objects can potentially prematurely damage it long before the recommended service interval.

Can a rubber timing belt damage my engine when it fails?

A small minority of engines are known as a “non-interference” design, which means, no matter what angle the camshafts are in relation to the crankshaft, the valves cannot hit the pistons. Therefore, the only thing that will happen if the engine belts fail is the motor will cut out. No internal damage will occur.

Unfortunately, the vast majority of engines are of an interference design. Therefore, if the belt fails and the camshafts either stop rotating or go out of time, unless you are incredibly lucky, you will suffer engine damage. This can vary from some bent valves right up to serious damage to both the cylinder head and block.

Timing chain

This is the alternative to the rubber cam belt and serves the same general purpose. A metal timing chain is the usual timing belt design for pushrod engines. This applies to a large number of overhead cam engines.

The main advantage is it is very low maintenance. The service life is much longer than a rubber belt. In fact, some are considered to be a lifetime part, not needing to be changed at all. Though most manufacturers and enthusiast owners would not agree with that statement.

The disadvantages are more numerous than the very clear advantage. However, they are all minor in comparison. This is why, overall, there’s a fairly equal spread of use between rubber and metal timing belts. Noise is slightly increased by the metal belt, as is cost of the item. Being a metal chain link belt means there’s less flex than a rubber belt. As a result, they don’t tend to twist around a complex belt routing and generally don’t run any accessory components. Labor time and cost to change a cam chain tends to be higher than a cam belt. However, as the frequency is reduced greatly, it’s another relatively minor factor.

No timing belt or timing chain? Gear drive

While it’s certainly rare, some engines don’t have any timing belt or chain at all. These are purely gear driven from crankshaft to camshaft. On some engines, even the accessories are directly gear driven. It’s fairly uncommon in production engines. Notable exceptions are certain heavy duty diesels, with some Cummins, Nissan, VW, and others all using a gear driven design. For race engines, this setup is actually very common. The vast majority of purpose built race engines are designed as pure gear drive, no belts or chains at all.

The advantage of this setup is it’s incredibly strong and reliable versus a belt. However, it can be noisy, and overall complexity and price is increased vs a belt or chain. In some cases, plastic gears and similar have been tried to alleviate the cost and noise issues. However, that then gives the reliability disadvantage of a cam belt, so is rarely seen.

Some engines have aftermarket conversions available to convert to a gear drive setup. Generally, though, people do this more for the supercharger style whine rather than any performance reason!

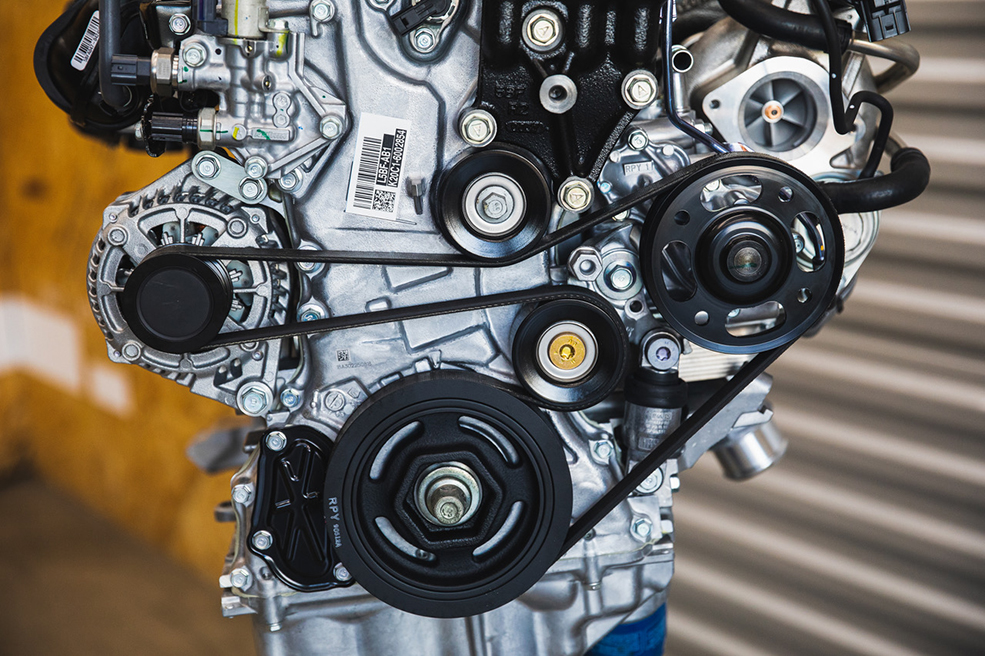

Serpentine accessory belts

To run your alternator, power steering, water pump, and other accessories, the most common solution is the serpentine belt. This belt is generally of a rubber multi-vee design and snakes (hence the name) around all the various accessory pulleys and idler belts of your engine, running them all from a single and neat, if relatively complicated, belt setup.

Just like a rubber timing belt, these are certainly service items with a finite lifetime. Generally, though, the results of one failing is far less catastrophic. However, depending on your engine, this can still lead to an immobile or overheating engine.

As their function is less important than a timing belt, orientation or even very slight slip is not an issue. That makes DIY replacement less of a daunting prospect, and cost of a new one is generally very low too.

Check out our guide to serpentine belts for more information.

Vee accessory belts

This style of drive belt is the most common design in the overall history of engine belts. That being said, it’s now rarer since the advent of serpentine belts.

It’s a rubber belt designed in a single vee shape. It tends to connect two or sometimes three pulleys together in a relatively straight path. This is instead of multiple pulleys and directions a serpentine belt tends to travel in.

A vee belt is generally the cheapest and easiest to fit drive belt. However, it’s also the most prone to slippage. Additionally, if you have a car with a lot of accessories, you may require a number of separate vee belts as they are far less flexible than the serpentine design. As a result, it increases the space needed and complexity versus a single serpentine design.

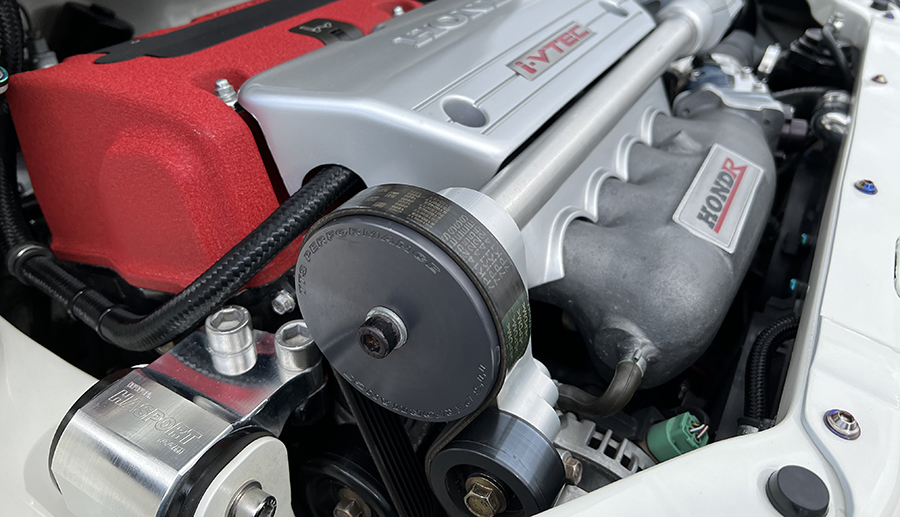

Gilmer/toothed accessory belts

A toothed accessory belt is one of those engine belts that is very rarely seen on production engines. When you have a situation where accessory belt slip cannot be at all tolerated, a toothed accessory belt setup is employed.

Usually found on race engines, these designs, sometimes called a Gilmer belt setup, use a rubber timing belt style design. They are employed for things like when dry sump oil pumps and mechanical fuel pumps are used, and where slippage can cause rapid engine failure. This design is also used as a supercharger drive belt setup in cases where slippage has been unavoidable with more conventional designs.

Noise is usually dramatically increased with these setups. However, when you really cannot have any slip, accept no substitute.

Supercharger drive belts

Aside from a few unusual setups, superchargers are almost always belt driven. On production engines and the majority of aftermarket setups, they use a serpentine style multi-vee belt. While generally this is very effective, as already mentioned, these belts can slip. Plus, the likelihood of this is increased with the heavy loads of superchargers; especially on tuned engines running higher boost pressures.

You may think this is a bad idea and the obvious solution is to simply run a toothed drive belt. While this certainly solves the slippage issue, it can create another potentially worse issue; belt damage or the belt coming off the pulleys.

On cars that see large amounts of rapid rpm changes, hard used manual transmission vehicles especially, the combination of the belt, crankshaft, and supercharger having trouble keeping fully in sync with each other can cause problems. While a multi-vee belt will accept a little slip from this issue, a toothed belt will not. This can lead to shredded belts or indeed the belt being thrown off the engine completely. This is why in general, toothed supercharger pulleys are reserved for drag cars, mostly with automatic transmissions. Supercharged road and circuit engines stick to the multi-vee belt as the mild slip it allows is actually beneficial.