Professional metalworker and YouTuber ‘TimWelds‘ has created a V8 cordless drill. And yeah, it’s as epic as it sounds.

We’ve all seen people chop and change powertrains before – pretty much every type of tuner car under the sun has had an LS swapped into it at some point. But this project is… certainly a novel idea to us. Yep, you read the headline correctly. This cordless drill has a miniature V8 engine where its electric motor used to be.

Tiny V8 Engine: In Detail

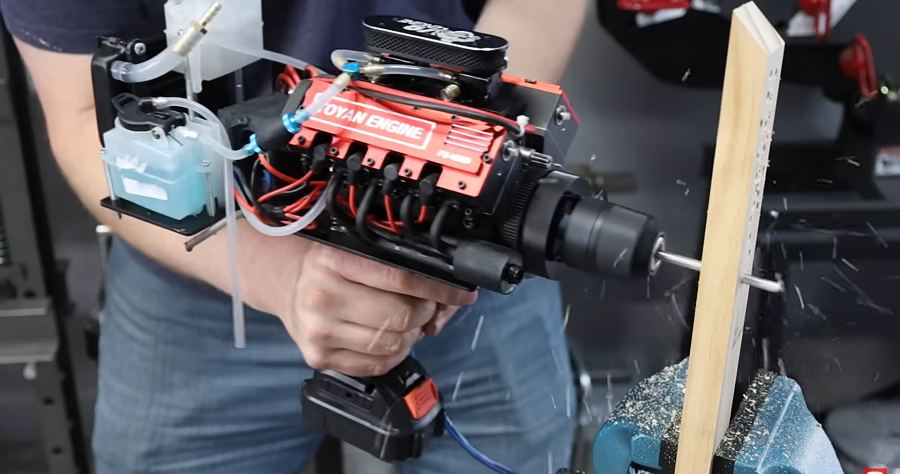

The first question you might be asking is, “where do you even get a V8 that small from?!”. Well, in this particular case, Tim used a Toyan V8 model engine which is typically intended for crazy high-end RC cars. You can buy these off the shelf, but unfortunately it’ll cost you a whopping $1699.99 to get your hands on one.

The engine comes as part of a kit, meaning that before you can start stitching it to your cordless drill like some sort of evil scientist, you have to assemble it first. The parts that make up the engine are all detailed enough to look like the real thing, albeit shrunken down considerably. However, while that’s a great testament to the quality of the product, it does also mean that you’ve got a pretty sizeable job on your hands to get this thing put together.

There’s no electric wizardry going on here either – this mini V8 is fully functional and very mechanical, and as such, it even has its own auxiliary cooling and fueling systems. As a result, the noise it emits when running does genuinely have the V8 undertones that we all know and love. It’s bizarre, but in the best sense of the word!

Design & Fabrication

So, you’ve got your tiny engine up and running, but what next? How did Tim go about planting this thing into his cordless drill? In short, it took *a lot* of hard work.

First off, he used CAD software to create an engine mount for the V8 to sit on, as well as its accompanying radiator and fuel tank, plus wiring. He then sawed a sacrificial cordless drill along the line where the handle meets the motor/drill housing. Tim then mates the handle to the bottom of the engine mount, before attaching the drill chuck to the engine’s crankshaft.

The process is one which took considerable planning, and a heck of a lot of skill. So, check out the full project in the video below, and make sure to go and send Tim some love for his efforts. Enjoy!